Got the ports back from hot tanking and made some interesting discoveries: the motor has been rebuilt before. The crank pulley bolt was lathered in blue loctite and the center iron is DEFINITELY newer than the front and rear irons. I measured the wear on the irons and the center and rear irons only came up with .002-.003 step wear max. the front iron came up with .004 step wear

Is this beyond the limitations of lapping? How much can you take off the irons with lapping and still be OK? If they aren't able to be lapped due to wear, i am working on a deal for an S5 long block to use so hopefully i can use those parts...

the rotors also seem to have a lip of sorts on the back part of the apex seal groove. Is this normal wear? the apex clearances were in spec before the rotors were totally pulled apart.

Also, can you lap the housings to eliminate pitting around the water seals? (if you look at the pics, i doubt my housings are useable anyways...)

Rear Iron (notice how rusted the hose nipples are)

Center Iron (notice how new and fresh the nipples are and the general condition of the iron)

Center vs rear

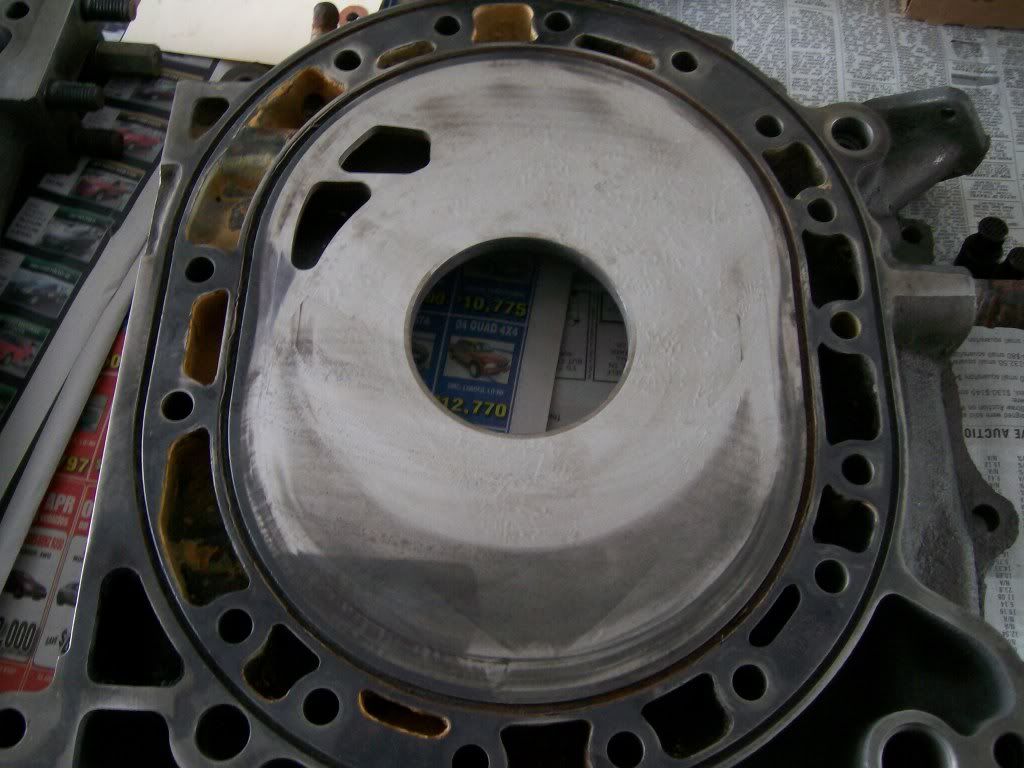

Front Iron (worst step wear of .004)

Front vs center