12-24-2010, 02:55 PM

12-24-2010, 02:55 PM

|

#74

|

|

Rotary Fanatic

Join Date: Jul 2008

Posts: 151

Rep Power: 18

|

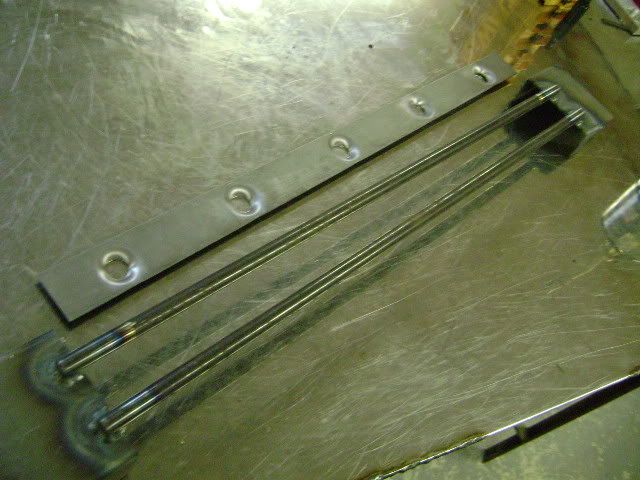

Have some more pics of the building process. We had to move the engine 1.75" further back into the chassis to make room for the large radiator and a/c. Started with a stock transmission mount, cut and fabricated a new structure onto it. Then, had our driveshaft shop shorten the driveshaft 1.75". Since the shifter would no longer line up, we used a 1st gen shift tower and modified the shift rod. This puts it very close to stock location.

Then built a oil pedestal bracket, and bolted the assembly to the shock tower. The pedestal will allow us to have twin -8an feed lines to front and rear of the block. We have found through racing that this is a desired modification.

Then built a oil pedestal bracket, and bolted the assembly to the shock tower. The pedestal will allow us to have twin -8an feed lines to front and rear of the block. We have found through racing that this is a desired modification.

Next was time to mock up the radiator and condenser, as well as the oil cooler. We relocated and fabricated the fill neck on the radiator to give additional hood clearance. Machined spacers were made, and the condenser bolts onto the radiator. Once the ideal locations were found, a subframe that holds both was fabricated. The subframe bolts onto the car, so no welding on the chassis would be required. This will be a quick release setup similar to my track car. The radiator, oil cooler, and condenser will be able to be removed in minutes from the top.

Next was time to mock up the radiator and condenser, as well as the oil cooler. We relocated and fabricated the fill neck on the radiator to give additional hood clearance. Machined spacers were made, and the condenser bolts onto the radiator. Once the ideal locations were found, a subframe that holds both was fabricated. The subframe bolts onto the car, so no welding on the chassis would be required. This will be a quick release setup similar to my track car. The radiator, oil cooler, and condenser will be able to be removed in minutes from the top.

__________________

DEFINED AUTOWORKS

Where concept meets results

Black 1994 FD 4-rotor 610rwhp all motor

Red 1970 Mazda R-100 with 10a

Black 1974 Mazda Rx4

Black 1984 Gsl-SE 13b-re streetport 230rwhp

|

|

|