Something happened here

More stuff goes to be powdercoated. The x-brace, the radiator bracket (revised for the third time), the slave cylinder mount, the steering rack brackets, the front LCA brackets, the engine cradle, and the trans bracket. Maybe some other stuff I don't know it's hard to keep track off honestly.

A neat picture with tubing nuts and sleeves lol

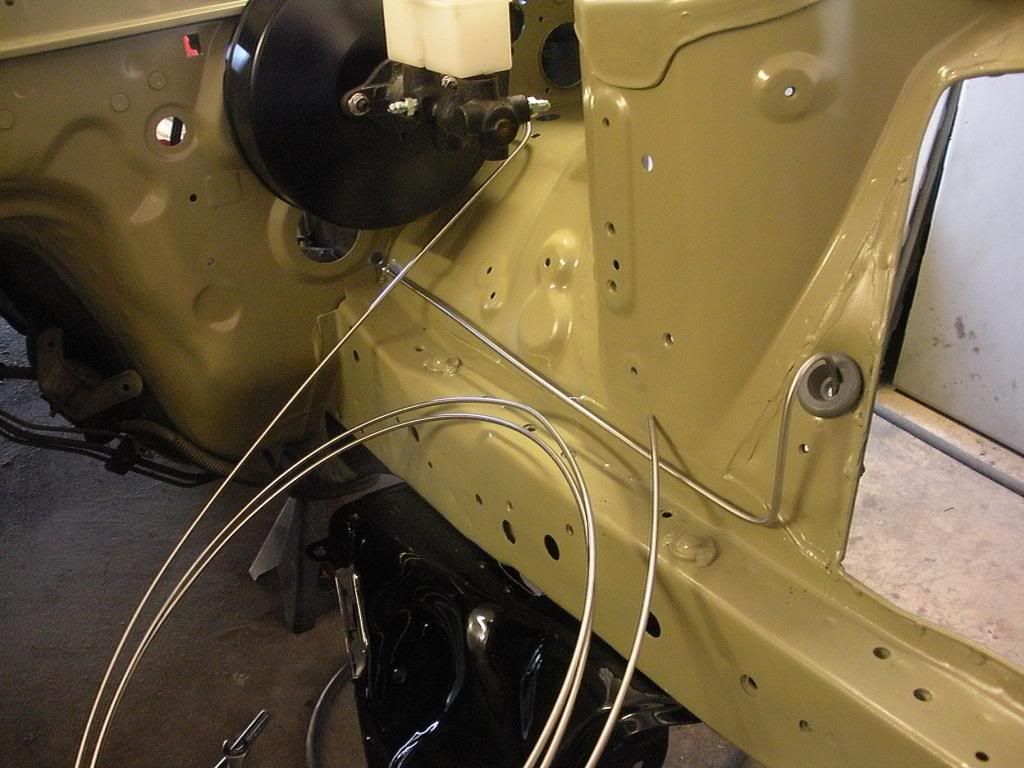

Painted the brake booster and loosely mounted it and the brake master cylinder. Began the process of building the MC lines to the firewall bulkheads. The proportioning valve will be inside the car. One problem with the FC factory MC is that it has two front outputs right off the MC. I had to buy a plug for one of the outputs so that there would be just the one. The fronts brakes divide after the proportioning valve now, more on that later.

Built the front brake lines up to teh bulkheads in the firewall as well. almost a finished product at this point.

I didn't like how the rear MC brake line was laying out so I started over lol.

Front line is on the right in the picture at the firewall.

Here's what's in the wheelwells. I used a staright -3AN bulkhead and bolted that through the brake line holder. All the brake stuff is now -3AN no more inverted flare stuff or any of that. Doing 37 degree flares is far faster and easier then doing double 45 degree flares, plus it looks cooler. I chose steel stuff due to the fact that is far more resilient than aluminium stuff. I don't need a brake line failure because a little rock popped a hole in something. Also the stainless stuff weighs such a small amount more it's not even worth mentioning really.