Alright, well I inspected the Apex seals. They are the classic 3 piece mazda style apex seals and they all measure within .1mm of 7mm in total height, there is very, very, very little warpage aka, unable to measure the warpage without causing the pieces to separate. So now I stand on the threashold trying to decide on if I should buy a new set of Apex seals (2 piece, or 1 piece) and if I do buy a new set, do I want to have them cryogenically treated or not... I'd like increased durability and reliability, but I'm not sure if it would be worth the increase in price. Any suggestions?

Here's some pictures of what's been accomplished so far:

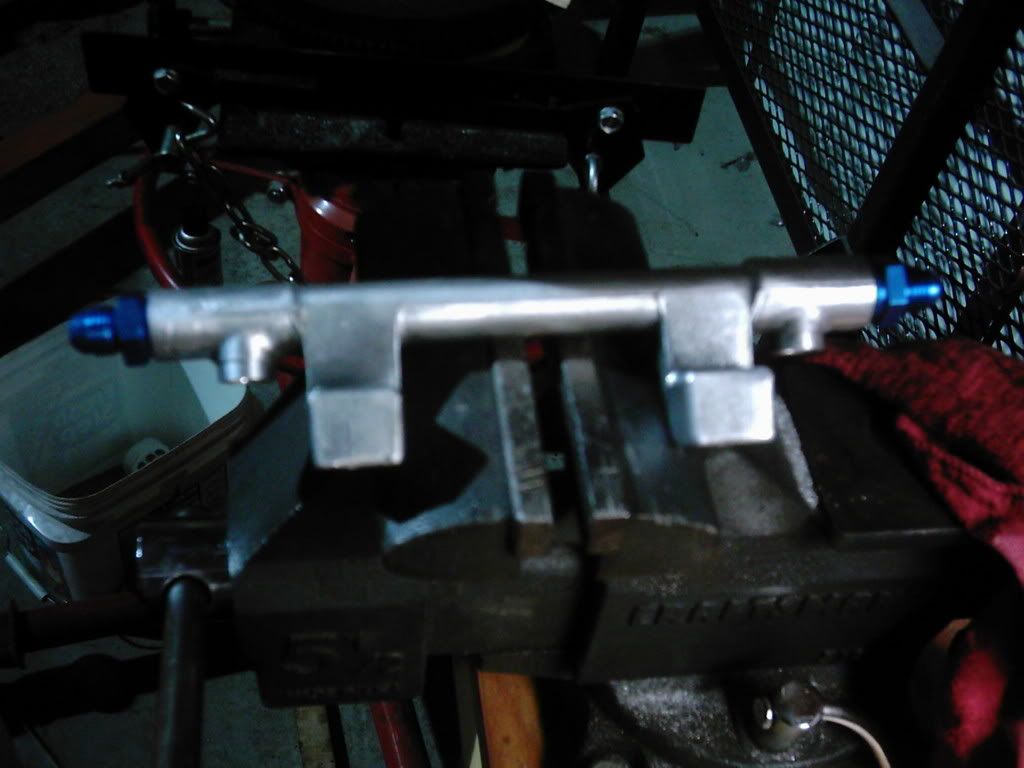

Drilled, and tapped secondary fuel rail. At some point in the future I may get rid of this and go with a KGParts fuel rail instead. But in the meantime I think this will work out nicely.

Rough look of where I want the new radiator to sit. I plan on relocating the oil cooler an inch or so forward and dropping the radiator down to have a complete perpendicular set up (no mo' angles).

Notice that there is no more "webbing" to restrict the movement or placement of the radiator.