Also, here is a list of suggestions that will help you understand a lot of the changes we wanted to make to the original GTC nose and the background on it all:

My Initial comments on replicating the nose and suggested changes:

I would definitely buy one in FPR, however here are a few notes that are very important conciderations when making this nose:

1) MOST IMPORTANT, is making it off a proper mold. I have had three different copied versions of the GTC nose and only made a decent fit. From what I found, the pettit copy uses the best mold and provides the best fitment as well as quality. The cheapo copies not only fit like crap, but also have uneven layed fiberglass and are to thin in some spots and to thick in others. The pettit version also covers the hole in the middle of the nose, another good thing in my opinion. I would make use the pettit copy as the baseline.

image from pettit site:

I have already had a few forums members ask me for advice on where to get a good gtc nose, and I tell them pettit, and there have been more than one case where they got a cheappo and it fit so bad they had to get a difference nose, got the pettit and it fit very well.

2) Modification to the current GTC design. I would like to suggest a 'race' version of the nose. IT would basically stay the same excpet for a few changes in the side ducting holes and possibly the corners of the bottom. I will save the details for later but basically this would allow for better oil/brake ducting and for better bottom mounting of splitters/undertrays.

I will give you guys a chance to respond with questions before I get into more detail.

Here I go in depth on some changes and show pics:

ok, here is a bit more formal description of the changes I am talking about to the original GTC nose. Most of these things are kinda hard to explain as they are 3D changes.

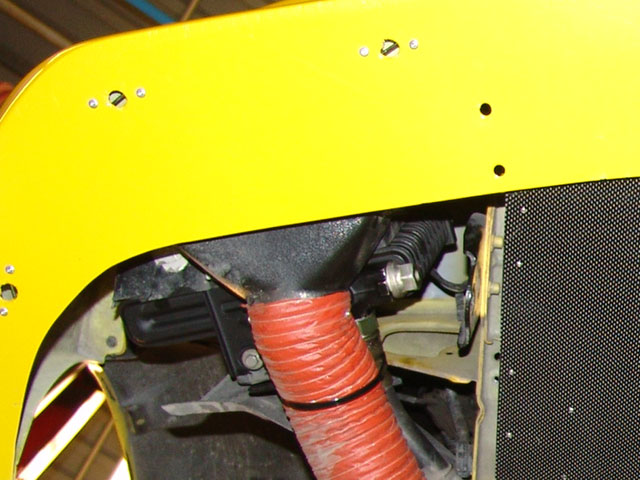

First lets talk about the oil cooler area, basically the walls of the oil cooler/brake duct area need to extend further, you can see in this picture below that we use the stock ducting to fill the gap to the nose.

Now this is based on the stock oil ICs, if you have after market ones you are on ur own :-) The stock oil coolers also sit at a slight angle to the front of the car, so the back wall of the nose would have to match that angle also. My concept would be that either the nose walls go back far enough to mate with the oil cooler and the purchaser can trim the walls as needed to fit their oil coolers or that the walls are made like .5 short of the oil coolers and the purchaser uses rubber stripping to fill the gap. Something like that, but definitely need it to go further back in that corner to mate with the oil cooler better.

Ok now, see in the picture below, the 'walls' that the two arrows are pointing to need to move. The vertical wall needs to move further out to open the hole more, basically instead of slanting in to wards the inside of the hole, the wall should go straight. Also the bottom 'wall' need to also not slant upward so much, rather go back more straight to open up the bottom part of the hole. This will play into the molding in of the brake duct that I will talk about in a second.

Now, I use standard duct like the 6.25" Deep, 8.5" Wide, 3" Hose (SPA - D100) that I get from here:

http://www.racerpartswholesale.com/naca.htm

You can see the back of it in the picture below:

Ideally these would be molded right into the nose, so all you need to do is hook up the duct hose. This is a bit tricky as the bottom of the oil coolers have fitting ends that make a problem getting the ducts in there, BUT if you lower the bottom wall as i mentioned above and then mold the duct shape in the nose, you can make it clear the oil fitting very easily and have a very functional brake duct molded right into the nose.

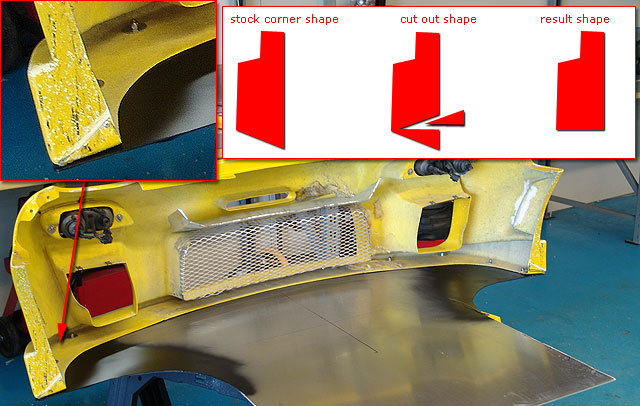

Ok, now the corners of the nose. The problem there is that fitting any type of undertray or splitter can be difficult as the stock corners of the nose make a non-flat shape. Look in the picture below and you will see what I mean.

This is easy to fix in a new mold, just make the end corners flat on the bottom and this issue will be solved.

Here is one that may be a big deal in trying to make a new mold, but is kind of an 'icing on the cake' kinda thing. The stock angle of the sides and bottom actually do tilt upward from front to back, as you can see in the red line i marked on the nose below. Again, we run into an issue again with splitters an undertrays, as we want them to be as flat as possible (unless you are making a full tunnel underbody, but that does not apply here..heheh). So, again ideally, you would have the sides rotated slightly so that the bottom make a flatter line, like the yellow like i marked in the pic below.

anyway, im just scribbling notes here... it may be hard to understand some of it but you get the basic idea. Maybe ill make a video of all this to explain it better :-)

Those posts and the video link above should give you a good idea on what we are trying to improve on with the new version of the nose. :-)