|

|||||||

| Piston Engine Conversion Have you replaced your rotary with a V8 or any other type of piston engine? Tell us about it! |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Piston Engine Conversion Have you replaced your rotary with a V8 or any other type of piston engine? Tell us about it! |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

Great, another V8 FC drift car build thread :/

Build threads are not really my thing since they consume a bunch of time and stuff like that (Which I never seem to have enough of). But I said I would so here it is for those who may or may not care.

Quick recap of the last few years. Had some FBs with 12As and 13Bs Didn't really like FC chassis for whatever reason. I honestly can't even remember why since I love this chassis now. Bought an NA FC to daily drive. 89 GTU. Did that for a bit, fixed minor stuff on it, made a proper road car out of it and all that. Got into drifting. Decided the FC was better for drifting than a FB, not for any fault of the FB but for the "off the shelf availability of parts". Coilovers are cheap and fenders and that sort of stuff. Built a decent drift/street car based off my NA S5 engine. Racing Beat road race exhaust, streetported, and a bunch of other stuff. Made approx 200hp at the flywheel probably. Nothing spectacular. Faster than a RX-8, so whatever amount of power that takes. Other stuff like the T2 rear end and delrin bushings throughout the car from MMR. BC Racing coilovers, knuckles, the usual stuff that ends up in these cars. I used the car for a bit of advertising for my company that is now closed due to lack of customer participation shall we say (Rotary Related). Still got to build dozens of cool cars and stuff. Had a lot of fun, made some money. Nothing crazy though. Had fun drifting it this season. It does quite well. here's a vid of the car through most of the events I attended in 2012. Some events aren't in the video, but who cares. http://vimeo.com/51454673 Anyways The car was good enough to have some fun and link most of the tracks no matter how big the entries and all that were. Mostly it would be on 205s in the rear and would almost have to be brand new tires to have the compromise between off throttle grip and being able to break the tires lose. Sometimes very frustrating to drive. Driving the car like this was a "one shot deal". you run the perfect line and do everything correctly and you look good and have fun. If you don't then you fail miserably and there's no coming back from a decent sized mistake, due to the fact the car just didn't make enough power. I drove my buddies SBC FC somewhere at the beginning of the year. At the time I drove it, it was not well setup and the engine had some issues. It still had more power than was necessary and I enjoyed the five or so laps I took in it. So easy to drive and gave you the freedom to roam around outside the line with no issues such as not having enough power to connect the next transition. I then bought a 13BT, street ported it and painted it, bought a BNR turbo Stage 4 S5 jam), a bunch of supporting equipment. Spent maybe 3000 bucks in a couple weeks. Was all ready to make at least 300whp. It was going to be awesome. Then that nagging feeling came back, about driving my buddies SBC FC..........oh that feeling.........the devil possibly, lol. So I sold all my recently purchased 13BT stuff to a friend who is putting together a FC drift car locally here. I still get to finish that up with him, and drive it and all that, so I feel I've won on both accounts. I wanted to make a purchase to lock myself into the swap. So i sold my S5 drivetrain to another friend locally so he could put it in his AE86, since the 4AGE sucks. We swapped it in, super easy to do btw. Using a GSL-SE transmission it fits quite well. Here's a vid of that car........just has coilovers and factory steering capability. Not bad for the shakedown of this thing. Also my Buddies SBC FC is in this video as well. He has no front end because he's lazy and didn't want to reassemble it before the event. http://vimeo.com/51958204 So after I sold that stuff to my buddy with the AE86 I bought the Granny speed shop small block Chevy mount kit (Locked in). You can mount LT engine's as well with this kit. Actually he just came out with adapters for the mounts to use the same kit to mount LS engines as well. Now your mostly caught up. No I don't care if someone doesn't like V8s in RX chassis, don't even bother arguing I'll just ignore you. I'm doing it for me and only me. Just about the only kind of engine I have not owned in any of my previous cars is a V8. I have gone back and forth with myself on this for over a year now. Then I finally decided "Fuck it I want it!" .......that is all. I may or may not have said 'Merica! I'll add some pics and what not pretty quick here of the actual build. |

|

|

|

|

|

#2 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

Here's the granny's kit.

I opted for the clutch slave cylinder mounting thing for a 4 speed transmission from an older Chevy (60-70s?). The older transmissions had mechanical linkage (Clutch cable I guess). Granny's makes a kit to bolt up a factory Mazda slave cylinder and gives you the clutch release fork and all that as well. The matching 3/4" bore Wilwood master cylinder to go with it was ordered as well. the only thing I'm lacking is the clutch hose. I'll just put AN fittings in the master and slave and get a stainless hose made. Simple stuff. I bought the bellhousing from a old guy in DFW that builds 60's era drag rails. Made a friend as well. I'm sure his knowledge will come in handy should I need advice. He's been building SBC and BBCs his whole life. Super nice guy as well. It showed up painted orange. It's aluminium so i will media blast it and leave it natural. Looks like this: a.k.a. pumpkin head.  The granny's kit comes with new hardware and stuff, but I absolutely despise black oxide hardware, and I dislike zinc coated steel bolts. So I spent like $90 on a bunch of stainless hardware to replace it all, I got a few extra pieces of hardware as well for other stuff. Got to start out baller then crumble to peasant status as time goes on. It's not all in this one photo but you get the idea. Bolt Depot plug.  Some pics of the Granny's driveshaft. Grant does good work I like it more than I thought I would. I need to aquire the front yoke still from a Camaro or something similar. Not a big deal no hurry, I have yet to buy the gearbox anyways.

Last edited by StephenSheppard; 11-12-2012 at 06:13 AM. |

|

|

|

|

|

#3 |

|

BOILED PEANUTS!!!

Join Date: Jun 2010

Location: Jacksonville, Fl

Posts: 257

Rep Power: 16  |

The fab work on that kit looks very good, looks like a pretty nice kit

__________________

www.rotarycarclub.com "The way a Rotary engine makes power is ferocious, much like having a chainsaw under your right foot." |

|

|

|

|

|

#4 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

I have a standard bore (4.00") small block 350 with rods, pistons, and crank I bought for $150.

I am still trying to decide how to approach the engine right now. I may build this one or I may end up buying a crate engine. It's pretty hard to decide honestly. there are so many awesome crate engines out there with basically any amount of power you can imagine. I'm trying to be realistic as far as money goes. I'm not rich I just play a rich guy on TV  That being said I looked into the factory rod to stroke ratio, to get familiar with the engine. Turns out it's got a 5.7" rod with a 3.48" stroke which comes out to 1.64:1 RL/S ratio which isn't great. Also turns out that you can buy off the shelf 6" rods and pistons with a raised wrist pin to fix this issue. That gets you 1.72:1 RL/S ratio. Much closer to the 1.75:1 ideal. Actually endurance engines run way higher rod to stroke ratio numbers but I'm just talking about stuff that anyone can buy quite easily. That will lower the amount of wear on the cylinder walls and produce more torque. Not that it needs more torque  Next was compression ratio. I looked up the casting number for my block and it's a 86 truck engine. 4 bolt main, 1 piece rear main, which is why I bought it. that and the fact it hadn't been bored over yet or had any machine work done to it. I'll be looking at probably 10:1 comp or a bit higher to get some efficiency out of this old monster of an engine. Or I could just buy a crate engine, but where's the fun in that? I don't know yet, the engine goes on the back burner for now. I need to get the chassis stuff all finished up and straightened out first. The engine is the easy part really. I could also buy a running engine that someone's selling. They don't cost a whole lot so it's not really a big deal. So with the 13B out of the way it was time to get to work on the engine bay which needed a ton of attention. I drilled as many of the holes and did as much of the prep work as possible that I knew would need to be done before repainting or any of that took place. What I started with after a year of rough housing around with this thing. BTW most of that damage was not me it came like that but I never repaired it. I just drove it a lot lol.

|

|

|

|

|

|

#5 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

|

|

|

|

|

|

#6 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

Here's the radiator and fan setup from my 13B that I will recycle for the V8 swap. It holds the temps down on a 13B at 7000rpm+ on 105 degree days for hours on end.......it should be more than enough for the 350. It's one of the last ISC FB radiators modified to fit the FC chassis after I took it out of one of my FBs. Buick Century fan is a pretty serious fan. It cut the fan cycles in half or less (Temp controlled switch via a relay), in comparison to a regular 16" fan. Also the radiator is a double pass which gives the coolant some time to slow down and dissipate heat. I had no such luck with Koyos and stuff like most people run. Also a 22psi cap helps

It's going to need to move forward in the chassis quite a bit judging by Josh my buddies car. Approx. 6-8" forward. It's too tall to stand up right. It would stick about 2-3 inches out of the bottom of the car. Here's what's hiding under the front bumper. An old repair from a collision with an immovable object while street drifting. That was dumb. I don't street drift anymore because of that lol. I threw this together to get the car drivable at the time.  NOM NOM. That frame rail was way worse. I straightened it with a 12lb sledge hammer a bit lol. I use the term straightened very loosely.  Just terrible.  Out comes the sawzall and the cut off wheel. On a side note my old HF sawzall pulled itself apart and caught on fire while cutting the passenger side frame rail lol. It only made it about 1/2 way through and then destroyed itself. Pretty cool.     Just a little bit of the bent part left. I can work with this now.   What it should look like.

|

|

|

|

|

|

#7 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

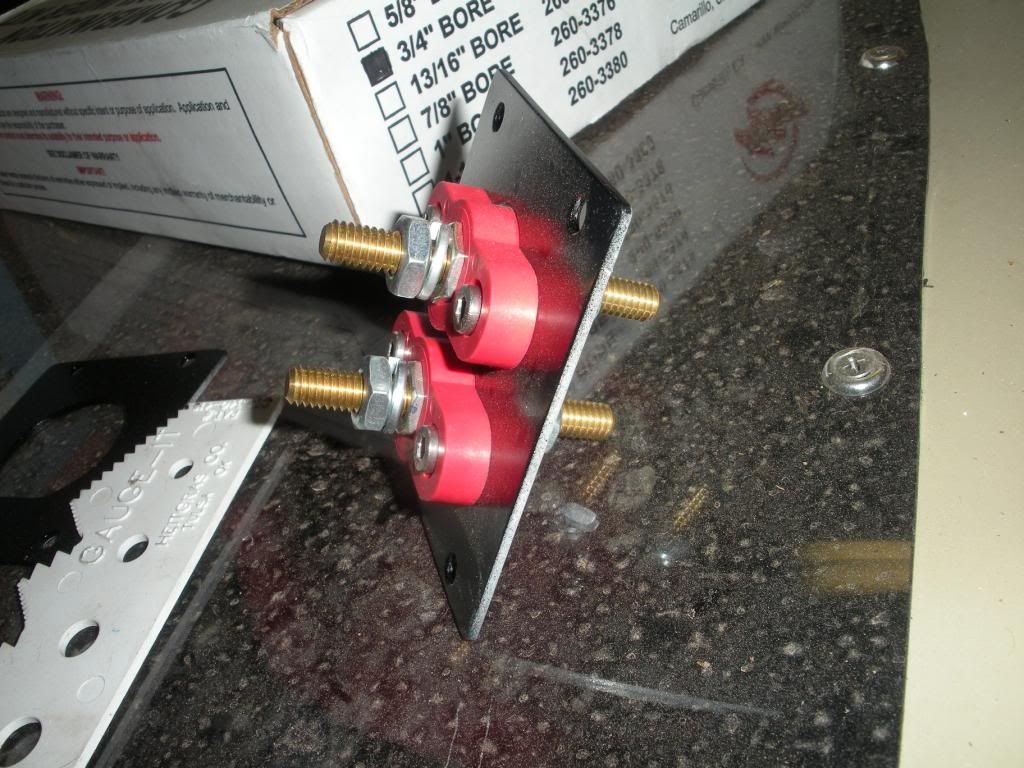

The other day I was sanding and cleaning and got bored with that. So I wandered off and started building this pass thru deal for the starter and alternator cables. It will mount on the inside of the firewall where the factory engine harness passes through the grommet hole. More on that later as the car progresses.

Btw you can buy those at VTE Warehouse, just Google them. They have lots of useful stuff. Normally I wouldn't share that but like I said the company is closed so full disclosure. Also my website is purely informational now and has a ton of cool stuff on it. Still in progress as there is so much stuff to upload yet. If you need to know part numbers for factory connectors and stuff for some of the Fc stuff you can find them here at the bottom of the page, the links under parts lists. Then look through the PDFs for what you need. Some of the connectors don't have links to purchasing locations due to the volume needed to buy them, but the part numbers are provided so you can Google them should you be lucky enough to find a few loose items out there in the interwebz. http://www.rotaryrelated.com/FC%20Race%20harness.html |

|

|

|

|

|

#8 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

Also made this dude for the driver's side grommet hole where the front wiring harness will pass through. It's painted black now like the one for the other side just no picture, I think you get the idea though. It's for a Molex XRC connector set. Has the anti rotation jam built in. The hole was achieved with a printed paper template, a drill bit, and a die grinder. It's just aluminium so it took like 5 minutes to make. Bolts up to holes I put in the chassis already like the other side.

You can find those at www.waytekwire.com and lots of other websites. The hole is cut for the 31 position connector. Which is more than adequate for the little amount of stuff I'm using. Scraped all the chaulking from the engine bay. I can't stand how it looks. I know I'm wierd and my car will probably rust in half because of it, whatever.  The interior is a train wreck right now. So much stuff to change, build, fix. New gauge cluster, new electrics for the whole chassis, cleaning, etc. At some point a roll cage has to get in here. So I'll have to notch the dash for that as well. I'm not sure what will come first. Still trying to figure out who's going to build what on this thing. Pretty much everything in that picture goes in the trash lol.

Last edited by StephenSheppard; 11-12-2012 at 07:23 AM. |

|

|

|

|

|

#9 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

So my old sunroof plug was leaking a bit. So I fixed it.

Still need to trim off the excess silicon and finish painting the roof. The reason there's over spray on the windshield is because it's cracked and being replaced so there was no reason to care really. Last edited by StephenSheppard; 11-12-2012 at 07:57 AM. |

|

|

|

|

|

#10 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

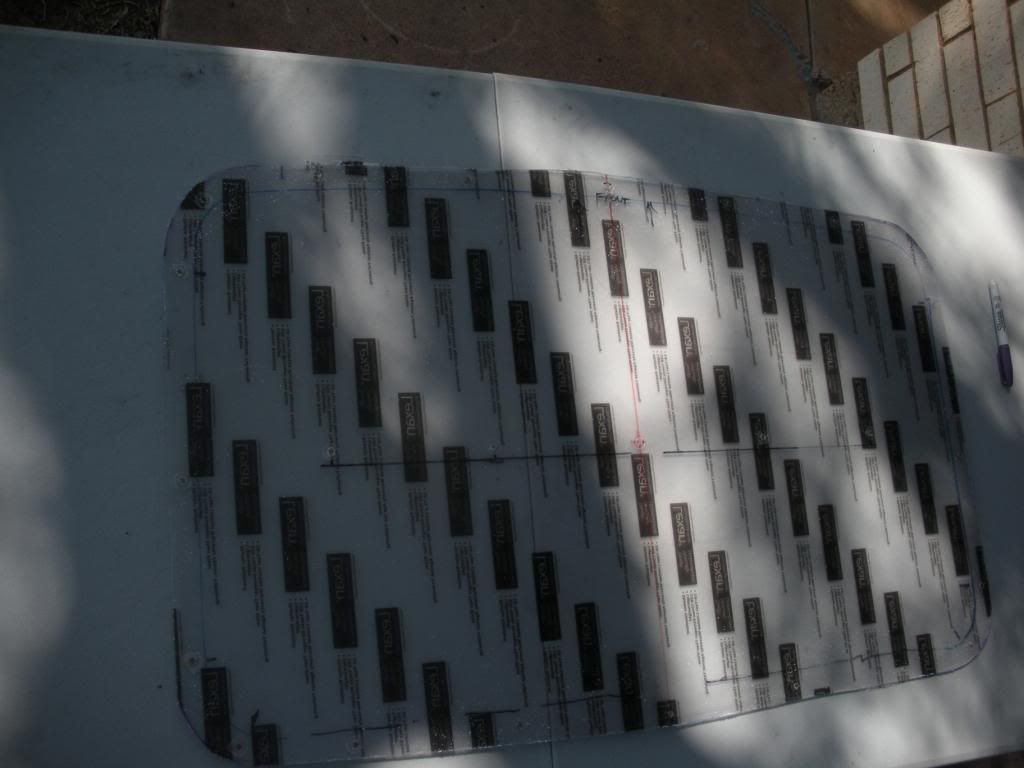

I don't like the door panels in my car because they are terrible, plus they had to go to make room for the roll cage. Here is my journey:

Started here with a modified T2 panel for window roller duty. has a hole cut in it due to the door not unlocking one time lol.  Everything must go!   Rivenuts for attaching the cards.    A crushed one. Basically they just clamp the material like a rivet. They are very secure if installed properly.  I used a piece of acrylic (Plexiglass) for the door card template, because it's cheap and transparent.   Temporary hardware for fitting. Yes my temporary hardware is stainless steel. I told you I have a problem   Cut the template up some more. The band saw works pretty good on this stuff. Oh I forgot to mention the sunroof is Lexan (Polycarbonate) not Acrylic. You'd have to have a death wish to use Acrylic there. If it shatters which it probably would it could saw your head off. No biggie, moving on.  Attempting to get the door release handle hole situated.  Window roller hole looks about right.  Giant piece of aluminium for the actual door cards. I was originally going to use ABS plastic but then I remembered I didn't want to be sliced to pieces if it shattered so I didn't.  The next bunch of pics were off my cell phone because the camera battery died, sorry. Here's a nearly finished door card fitted.  Then I was coming up with possible door handle pull options. this ones pretty simple and very sturdy. I may go with it, but I still haven't decided yet.    The passenger door is super easy because the template is already made. Punched out the factory clip holes to the size for the rivenuts, bolted up the template, marked the other holes. drilled those, put the rest of the rivenuts in. Boom! done.  Passenger door just before drilling the second set of holes. Also all this gooey black stuff needs to be removed so I can repaint the door. Plus I don't want it to get all over everything.

Last edited by StephenSheppard; 11-12-2012 at 08:17 AM. |

|

|

|

|

|

#11 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

I'll have to post pictues of the finished door cards when I get them squared away. They will be covered in Di-Noc or painted with black wrinkle finish paint. Still undecided. Had an issue with some "Di-Noc" I bought from a dude on ebay. It was not 3M Di-Noc and it was junk so, I'll order some real shit and see what it's like instead.

Plan B isn't bad looking either. I've done a couple cars with the wrinkle finish black and it looks really good. |

|

|

|

|

|

#12 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

The plan so far is this:

BCL Wing rear diffuser 30mm garbage ass fiberglass front fenders same for the rear over fenders new sideskirts (MOAR lower) carbon fiber hood that will clear stuff in the engine bay Might keep my factory S5 bumper, corksport lip and build a new splitter repaint the car repaint the engine bay repaint everything really fabricate a bash bar system or some sort tub the front end more than likely roll cage (Mentioned that already) Probably new wheels 17x9.5 0 or 12 offset I think that about covers it, then on to the drive train stuff. I already have a T2 clutch type rear end under the car and a dual 3" exhaust for the new engine. There's not much left to buy for the suspension. I may make some new knuckles with more steering angle since the front swaybar is coming off now. I'd be pretty happy with 60 degrees I have around 51 or so right now. Which is probably good enough. But with more power from the engine I'll be able to use more angle all the time so I may add some more. Tons of stuff to do and buy. |

|

|

|

|

|

#13 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

So got a bit more done today. Ground down the cross tube brackets and got rid of them so I have all the room I want/need to mount the radiator. It took awhile, I'm pretty sure those damn things are forged in the fires of Mordor.

Much better now. And it looks better as well.  Thinking about mounting senarios for the radiator now. First option like factory but moved forward. Makes ducting the nose of teh car super easy. I am leaning towards this option. It doesn't afford the radiator much protection though.  Option 2 is just inverted compared to the factory mounting. A bit more protection offered since the radiator is only near the front of the car at a very low point where cars usually don't get crushed.  Option 3 although most people would think this wouldn't work. It would indeed work quite well. Offers the most protection again bashing since it's so low but allows other damage to maybe happen from cones, tires, debris, etc. Basically laying flat in the nose of the car. I did have it tilted a bit upward in the picture though.  We shall see. I'm not sure what I like most yet. |

|

|

|

|

|

#14 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

Some comparison pics are in order I think. Here's my buddy Josh's car with the "I don't give a shit about how it looks I just want to drift" approach.

If you use a HEI distributor, you can expect to have to bash the firewall in. Perhaps you could bash it a bit better than this though. I won't be using a HEI distributor for this very reason. Also his windsheild wiper linkage is not capable of movement anymore  I'll be using a standard diameter distributor. I'll be using a standard diameter distributor. What you can expect for clearance on thedriver's side.  Passenger side clearance.  Clearance around the starter area.  This shot gives you an idea of the length of the engine.  Same thing on the other side.  So basically it fits fine, selecting components is important ahead of time. He pulled this whole thing out of a 3rd gen Camaro he had and just pretty much threw it in the car with the Granny's kit and called it a day. Utilizing the factory style mechanical fuel pump and all that sort of stuff. He doen't really have any issues after a couple small things were sorted out. has higher compression, bored over and all that junk. Whatever it makes more power than is necessary all the time. I'll be mid-mounting the alternator on the passenger side to lower the height and have a better fitting hood and fancy stuff like that. Also cause I'd like to use a factory carbon fiber hood if possible. I'll be spacing the rear of the hood up for added clearance for the air cleaner. Unless I go ahead and fuel inject it. Still contemplating that, as it will make the project take longer and cost far more. Decisions, decisions...... |

|

|

|

|

|

#15 |

|

Rotary Fan in Training

Join Date: Nov 2012

Posts: 58

Rep Power: 14  |

And then this happened :/

Got tired of looking at all the rub marks on the underside, and considering I will be using a larger diameter wheel and tire combo in the future, the fender wells simply had to go.     This rubbing action was due to a older set of wheels with less offset and a bad alignment. This wheel just barely clears as you can tell. Thats a 10.5" wheel with a +12 offset btw. So a 9" or 8" with the same offset would have a lot more space obviously. My target is a 9.5" with a 0 or a bit more offset so. No issues whatsoever. Plus the sway bar is going away. I won't need it anymore   Lots of room in front of the wheel. I didn't have to cut that much material out but I'd rather add material then live with the million-holed factory sheet metal.  A bit aggrevating, So there's never a hole where you want it. So I made a new one reluctantly above the factory harness pass through.  For this grommet. Just for the windsheild wiper harness and fan relay harness. Super lame but I don't want to run that stuff from across teh engien bay, as it looks tacky / messy.  Over sized the brake line holes to 1" for these same grommets for the brake lines. The factory ones are long since deteriorated of course. I'll trim the nose as it over shoots the holder just a bit.  Those grommets can be found here: https://www.vtewarehouse.com/content...SeriesPage.php Probably supposed to put this in the for sale section but I put it here anyways. $60 shipped Front swaybar endlinks (Mazdatrix) and Energy Suspension factory diameter bar bushings and brackets. Here's the link to the Mazdatrix site for the endlinks I'm selling: http://www.mazdatrix.com/getprice.asp?partnum=H-M010F Link for the ES bushings: http://www.mazdatrix.com/getprice.asp?partnum=H-95128 Also I have the Granny's speed shop swaybar spacers for sale. Brand new never mounted to my car. $30 shipped Link: http://www.grannysspeedshop.com/ Or $85 for all of it shipped. OBO of course. I don't need the parts and a bit of loose change towards the car helps.  My contact info is: rotaryrelated@live.com 559-633-0376 (Stephen) also a link to my FB account from my website www.rotaryrelated.com (In the top right corner) Now it's time to reverse the cutting proccess into the building proccess  It might take awhile for me to decide what I want to do and update this. So many possiblilities............. It might take awhile for me to decide what I want to do and update this. So many possiblilities.............

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|