Time for a little update!

Sadly my HTC Desire isn't the best camera in workshop-lights...

Have finally got along with the Keyway!

First, I did new irons to the vise (correct name? Google translate)

They are mounted from the inside with M10-bolts

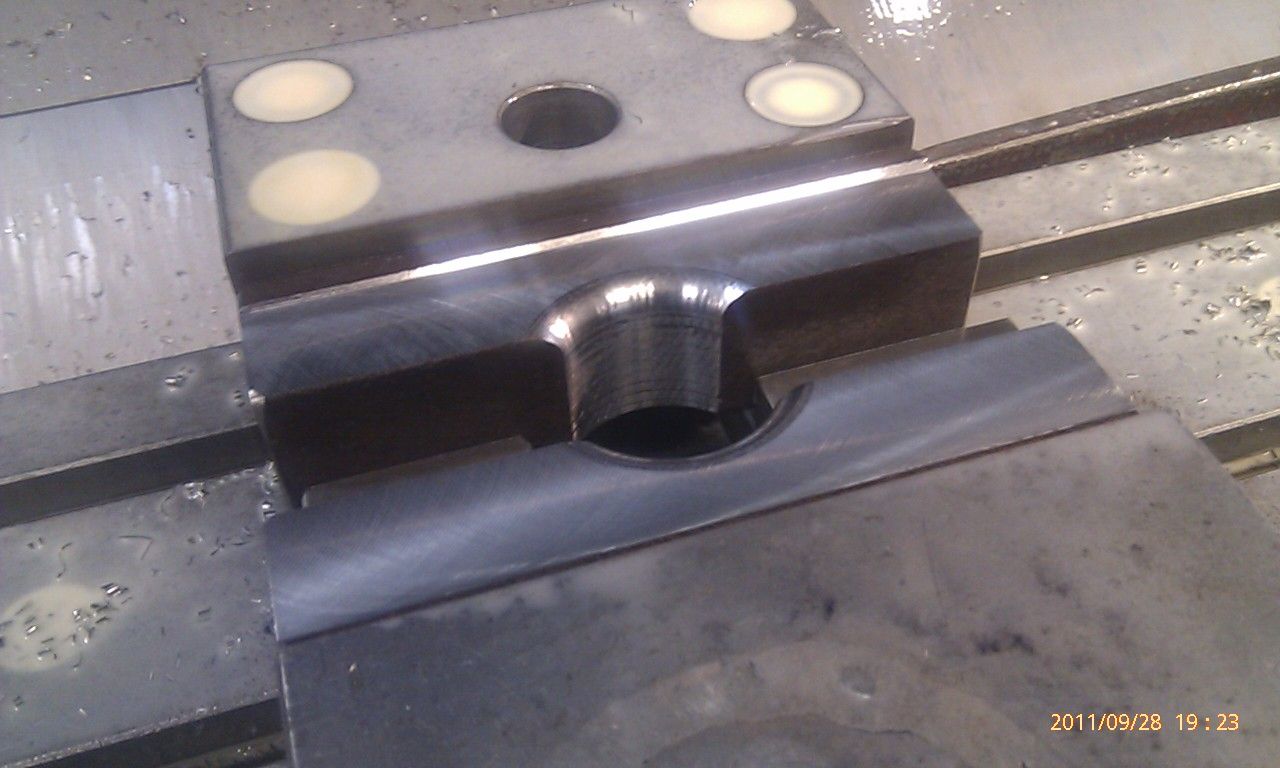

A hole at 43.61mm, and an Radius 6.0mm to give clearance for Radius 5.0mm on the eccentric.

This is not bored, so the surface is just roughed yet.

Exact precision!

Like a glove!

Indication of a cam, I have my zero point where I did the fixture, so then you have easy track of the eccentric theory should lie on the X 15.0mm Y0.0mm.

A final inspection of the tool. Indicates the track of the tool in the X-axis, thus I know that it is angled precisely 90grd.

Using the M-code M19 in the machine, so I lock the spindle in the same place every time.

This is what working out, it will actually go much faster, when the cutting speed in such a cut is about 80-120m/min, ie as soon as it will go through the material. Easy as it spins to get the cutting speed, but now the cut stands still. So I drive 2m/min

or F2000.0 as many may know. Takes just 0.1mm per insert to avoid accidents in my fine pieces

Results! Keyway on 5.00-5.01mm width, and depth with little clearance.