|

|

#76 | |

|

Don Mega

Join Date: Dec 2008

Location: Utopia

Posts: 1,688

Rep Power: 18  |

Quote:

Very wide! D shaped and extremely tall too. Was almost identical to my old Peripheral Port 13B from back in 1992!

__________________

www.riceracing.com.au Worlds best Apex Seals Coil on Plug Water Injection ECU Calibration |

|

|

|

|

|

|

#77 |

|

Rotary Fanatic

Join Date: Mar 2008

Location: chatsworth, california

Posts: 349

Rep Power: 18  |

very impressive build! i like your choice of volvo too!! my first car was a 122S

__________________

rotaryshack.com |

|

|

|

|

|

#78 |

|

Bah!

Join Date: Mar 2008

Location: Riverside, SoCal

Posts: 442

Rep Power: 18  |

Nice, CNC broacher!

__________________

Johnson TA FC in the works! |

|

|

|

|

|

#79 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

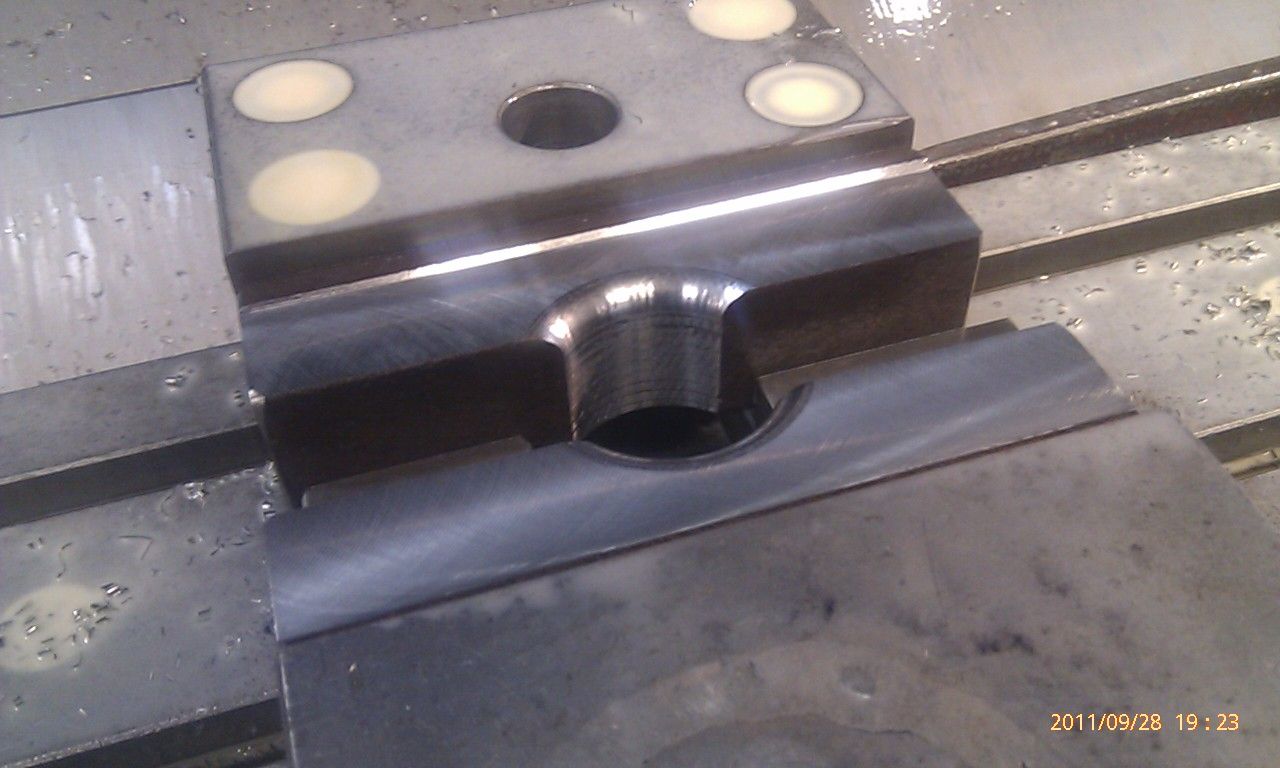

Time for a little update!

Sadly my HTC Desire isn't the best camera in workshop-lights... Have finally got along with the Keyway! First, I did new irons to the vise (correct name? Google translate) They are mounted from the inside with M10-bolts  A hole at 43.61mm, and an Radius 6.0mm to give clearance for Radius 5.0mm on the eccentric. This is not bored, so the surface is just roughed yet.  Exact precision!  Like a glove!   Indication of a cam, I have my zero point where I did the fixture, so then you have easy track of the eccentric theory should lie on the X 15.0mm Y0.0mm.  A final inspection of the tool. Indicates the track of the tool in the X-axis, thus I know that it is angled precisely 90grd. Using the M-code M19 in the machine, so I lock the spindle in the same place every time.  This is what working out, it will actually go much faster, when the cutting speed in such a cut is about 80-120m/min, ie as soon as it will go through the material. Easy as it spins to get the cutting speed, but now the cut stands still. So I drive 2m/min  or F2000.0 as many may know. Takes just 0.1mm per insert to avoid accidents in my fine pieces or F2000.0 as many may know. Takes just 0.1mm per insert to avoid accidents in my fine pieces  Results! Keyway on 5.00-5.01mm width, and depth with little clearance.

Last edited by Tegheim; 10-01-2011 at 04:22 AM. |

|

|

|

|

|

#80 |

|

Bah!

Join Date: Mar 2008

Location: Riverside, SoCal

Posts: 442

Rep Power: 18  |

I like this.

"First, I did new irons to the vise (correct name? Google translate)" We call these "soft tooling" since they're made of softer material that's easy to machine.

__________________

Johnson TA FC in the works! |

|

|

|

|

|

#81 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

SolidWorks is an hard program to learn...

|

|

|

|

|

|

#82 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Spaghetti maker?

|

|

|

|

|

|

#83 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

No more rise in my japanese engine

Tonight I made a little keyway in the crank, which corresponds to the ones I did in the eccentric. A male cutter, one must have ...  Important to buckle without moving it!  Finished setup.  work work  That did it! The track is 5.01 mm wide and 43.5 mm long. Easy to forget compensation for the shaft shall be grinded then when you set the depth.

|

|

|

|

|

|

#84 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Thats cool.

|

|

|

|

|

|

#85 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#86 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#87 |

|

20b Tinkerer

Join Date: Jun 2010

Posts: 15

Rep Power: 0  |

I love this thread. I bought a cheap mill and lathe a while back and taught myself in hopes of doing something like this one day. It's good to see how it really gets done though.

|

|

|

|

|

|

#88 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

Just for fun...

|

|

|

|

|

|

#89 |

|

cxxxx|::::::::::::>

Join Date: Nov 2009

Posts: 315

Rep Power: 16  |

so when can we see a 26b kit from you

|

|

|

|

|

|

#90 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

In this speed, about 2025?

|

|

|

|

|

| Bookmarks |

|

|