|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Show your rotary car build up. Show off your Rotary Car build! |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

My ongoing project car

All right, this month I'm redoing my HBP engine.

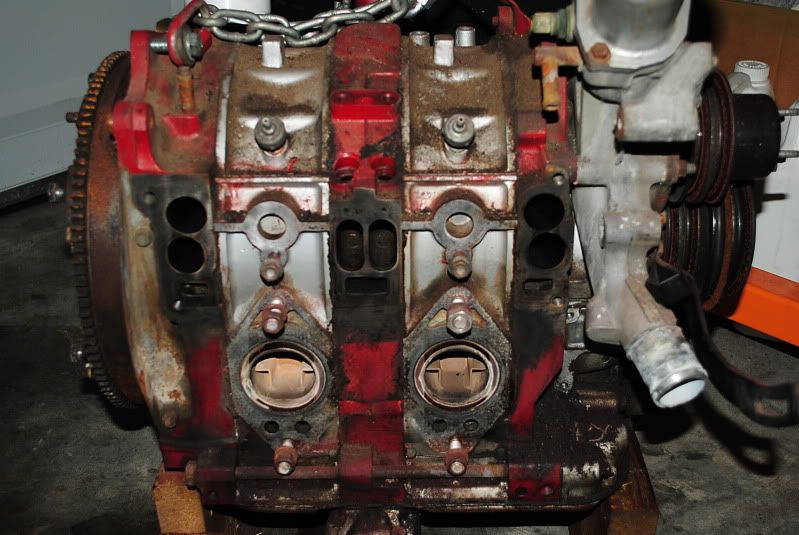

I'm actually going to tear down both motors I have and build up one good one. First off is the original S5 NA motor that was in this car. Some history about this motor: I did a rebuild on this motor back in 2005 with the help of a builder. I did this cause I was totally new to rotaries. I wont mention or bad mouth the builder cause he kinda taught me what I know about doing rebuilds. This motor ran really well till I swapped in the S4 bridge-port. Ive put about 55k miles on this motor. It drank a 1/4 qt of oil every 1500 miles it seemed. I had it dynoed once, and it only made 131rwhp. I raced a stock na subaru impreza wagon once and was even. Toward the end of the last few thousand miles I put on this motor, I revved the hell out of it and I bounced it off the rev limiter a couple of times. Well today I tore it down, and this is what I found.   If you look carefully, you'll notice that there are no corner seal plugs in this side of the rotor!?   All the other corner seal plugs have been located. So 3 were not installed. Build up of ? junk.  The porting on the center iron.   Im going to use this center iron and the stationary gears from this motor cause the bearings look better than the ones in the S4 motor. That's it for today.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. |

|

|

|

|

|

#2 |

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

The ports are shiny, the rotors look to be ok (you will need to check clearance to be sure).

I don't like the shape of that port. This design is giving up significant low end without making any improvements in the high end because that port has about a 15 degree later port close, but it is at such an awkward angle that it will not help chamber charging at high speeds. For what it is worth, I made 138 WHp on a bone-stock s4 6-port block, factory ECU, modified AFM (lean the mix up a little) and stock exhaust. Stock intake manifold too. This doesn't bode well for the porting on your engine that made 14 Hp more stock than mine. (What I am thinking is that the port design is actually hurting your power.) If I were you, I would start with a new stock center plate and port it yourself. Otherwise, it looks like you got an excellent starting point.

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) |

|

|

|

|

|

#3 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Ports are...OK.

They are not the best, but I've seen a lot worse... There are some builders who refuse to use the stock corner seal plugs. So those will tell you it isn't a big deal yours are missing. It's weird that only one side is missing... hmmm Gunk in the water passages are normal. Never did a coolant flush recently, right? It's aluminum oxide from galvanization of the rotor housings from dissimilar metals and an electrolyte (i.e. the coolant). You can't really prevent it; you just gotta deal with it. This is why coolant system flushing is recommended as maintenance. -Ted |

|

|

|

|

|

#4 |

|

Waffles - hmmm good

Join Date: Aug 2008

Location: Huntersville, NC

Posts: 757

Rep Power: 0  |

My stock port 12A makes 134 rwhp, so its a good thing you swapped in that

bridge port later. Looks like a fun project.

__________________

1980 GS stockport, Fat Nikki, RB Dual Facetfuel pumps, Holley regulator, RB Street port exhaust, 2GDFIS, MR2 MK I electric fans, 2G strut bar, relayed fans, lights and fuel pump, LEDs Project Fat Nikki Budget 12A rebuild Video setup < $30.00 |

|

|

|

|

|

#5 | ||

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Quote:

Quote:

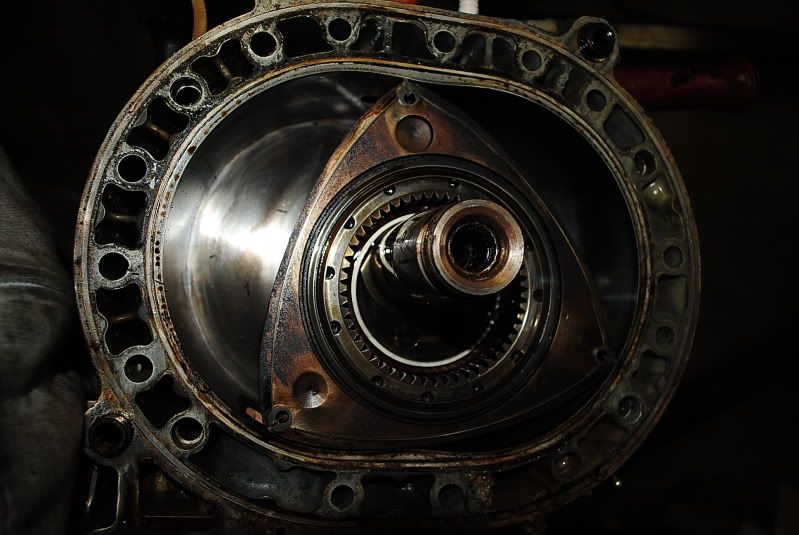

I suppose that this porting might be hurting the performance. Let me just say this: with the S5 motor I had in there, It pulled from 3.5k-6.5k rpm but just runs out right at 7k. Redlines at 8k. Buzzer at 8500. Rev limiter at 9k. With the HBP motor I have in there, it really opens up around 5.5k rpm and wants to keep going at 7k rpm. But some of the last times I drove it, it bogs down after 7k rpm, probably for some reason being with the stock ecu. I just know there was and is a big difference in performance with this HBP motor compared with the S5 motor. I can feel it. I love this HBP motor and wouldn't go back. Now for the decision of if I should stick with the stock port center iron that's in the HBP motor, or if I should swap with this ported S5 center iron. It would probably depend on the whole debate of if ported center irons increase or decrease power, etc. Stock ported center irons would probably be better, but I'm going with the ported iron just to see what happens. Ive already experienced the stock center iron with this HBP motor. Why not see what its like with a ported center iron. This is a bridge ported motor, so I'm not really too concerned with the low-end performance anyway. Anyway this is what the end irons already look like.   With this rebuild I'm just going to clean up the ports. But mainly this rebuild is about putting new o-rings and gaskets in. |

||

|

|

|

|

|

#6 |

|

Senior Member/Lounge Rat

Join Date: Mar 2008

Location: Corbin, KY

Posts: 296

Rep Power: 18  |

Is that a gouge in the face of that last plate?

|

|

|

|

|

|

#7 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

ha ha, yep.

That's a mistake I made the 1st time I ported it years ago. I don't think it affects any thing major. Maybe some carbon will build up there. Look at it this way, Its an experiment to see how gouges in the surface of an iron effect performance / longevity of a rotary motor.

|

|

|

|

|

|

#8 |

|

Senior Member/Lounge Rat

Join Date: Mar 2008

Location: Corbin, KY

Posts: 296

Rep Power: 18  |

Hahaha and clean them ports up man!

|

|

|

|

|

|

#9 |

|

RCC Addict

Join Date: Feb 2008

Location: VA

Posts: 1,812

Rep Power: 19  |

Those ports are U-G-L-Y.... I wanna see how they clean up when you're done.

|

|

|

|

|

|

#10 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

I got the engine out of the car this morning. Only took 4 hours.

Next: Take engine apart. Clean parts & do a little port work. Check out rotors and compare them. Get every thing ready to be put back together. Gasket kit should be arriving Wednesday, so it will be going back together after that day. |

|

|

|

|

|

#11 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

So I just took off all the things attached to the block, (manifolds, omp & lines, water-pump, etc.)

Well after I took the exhaust manifold off I looked into the ports and saw a puddle of coolant in the front rotor chamber. Confirms bad coolant seals, or reused ones, lol. That's all I have to report. |

|

|

|

|

|

#12 |

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

Wow! I didn't see the secondary ports when I made my comment. The way you have opened up the secondaries, that later closing on the primaries won't make any difference. You might as well leave it alone (what is the point of closing the primaries when the secondaries are still open).

I thought this was more of a daily driver, my apologies (I should have seen the HBP in the title - I thought this was a ported S5 NA). Good luck with the build. Get some dyno numbers, I would be curious if you can get 200WHp out of this build.

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) |

|

|

|

|

|

#13 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

If anyone is confused,

I have two motors, one is a street-ported S5 na, mainly the primaries are ported. the other is my Bridge-ported S4 na, mainly the secondaries are ported. Im planing to use the S5 center plate in the S4 engine. I also plan to use the 9.7 compression rotors from the S5 engine, if that's what they are. Also plan to use the stationary gears from the S5 engine because there in better condition. And will probably use the oil pump too. This afternoon I'm going to take apart the S4 bridge-port motor. Dyno & performance? When I ran this HBP engine before, according to my butt-dyno I could spin the tires around the top of 1st and cherp 2nd, this is with an open diff. Im going to swap in a LSD along with this build. I heard from someone, that with an LSD if you can spin or cherp the tires, you might have around 200hp. With this build, this time around, its not really all about the porting or the center plate and its porting. Its first about replacing the O-rings and gaskets with new ones, second its about the porting. Any other bits of info are... I'm thinking about... Going with the S4 intake manifolds. And stock ecu for now. Getting a exhaust header. Going with out power steering, taking the bracket and pump out, since the original pump went bad. And thinking of aux oil injection. Peace.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. |

|

|

|

|

|

#14 |

|

RCC Addict

Join Date: Feb 2008

Location: VA

Posts: 1,812

Rep Power: 19  |

A HBP w/ S4 manifolds and stock ecu? What's the point? If you have the S5 manifolds, why don't you want to use them? Also... I highly recommend an aftermarket ECU or at least a retuned stock one. The stock ECU doesn't perform well with a BP motor.

Of course, you can run the engine and putt around until you get that ECU squared away, but it's kinda like having a super model girlfriend who's still "saving herself"....  Good luck with the build. |

|

|

|

|

|

#15 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Stock ecu is just temporary.

S4 intake manifold is just simple. I don't want to mess with the vdi. Sure, I've heard that you get an additional 5-10-15 HP with the S5 vdi, but is that with it still functional? Or can you get away with it wired open? The S4 manifold eliminates that uncertainty. lol. |

|

|

|

|

| Bookmarks |

|

|