|

|||||||

| Fabrication Show off the parts that you've built from scratch or highly modified |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Fabrication Show off the parts that you've built from scratch or highly modified |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Don't get me wrong everything has it's place. Soldering can make seamless connections between wires, though as has already been mentioned they can become sources of failure. The best application of connective products is their appropriate location. For permanent connections with minimal movement a good solder joint is hard to beat. For locations where movement is expected crimps will be the best bet. Additionally one need be keenly aware that there are different types of solder and they're engineered for specific applications with different flexibility, heat, and electrical conductance.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

#2 |

|

Rotary Tuner in Training

Join Date: Jan 2009

Location: Beaverton, OR

Posts: 69

Rep Power: 17  |

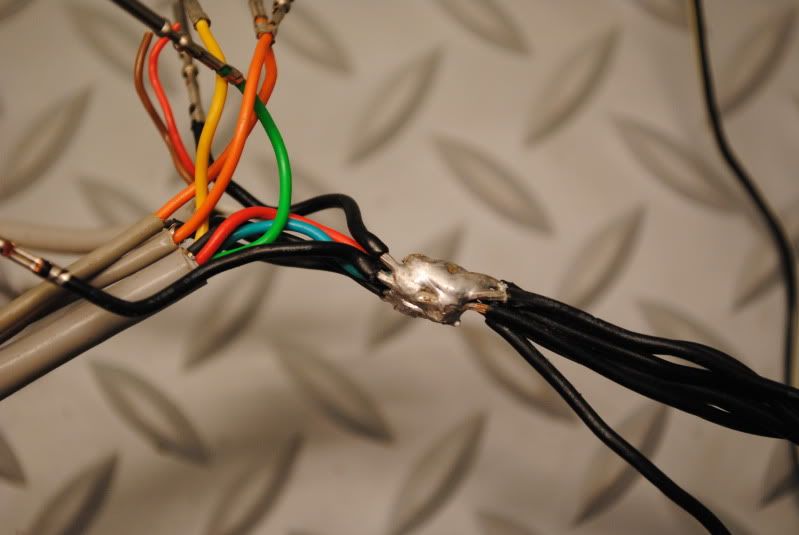

This is from my Haltech E6X harness. I bought it brand new.

|

|

|

|

|

| Bookmarks |

|

|