|

|

#91 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

|

|

|

|

|

|

#92 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

some progress, spaced the widening plate out 20mm from the base plate, and applied some foam and tried to shape it towards the door, not real happy with the result, need to change some things, maby start tapering it inwards earlier.

|

|

|

|

|

|

#93 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

|

|

|

|

|

|

#94 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

Last edited by Pettersen; 10-28-2012 at 09:58 AM. |

|

|

|

|

|

#95 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

Need to get my new flywheel from the states before i can set the endfloat and finish the shortblock. In the mean time i will get started on intake manifold and exhaust.

|

|

|

|

|

|

#96 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

So plans have changed, got some advice from some forum members wich turned me away from sequential throttle control, atleast at this stage.

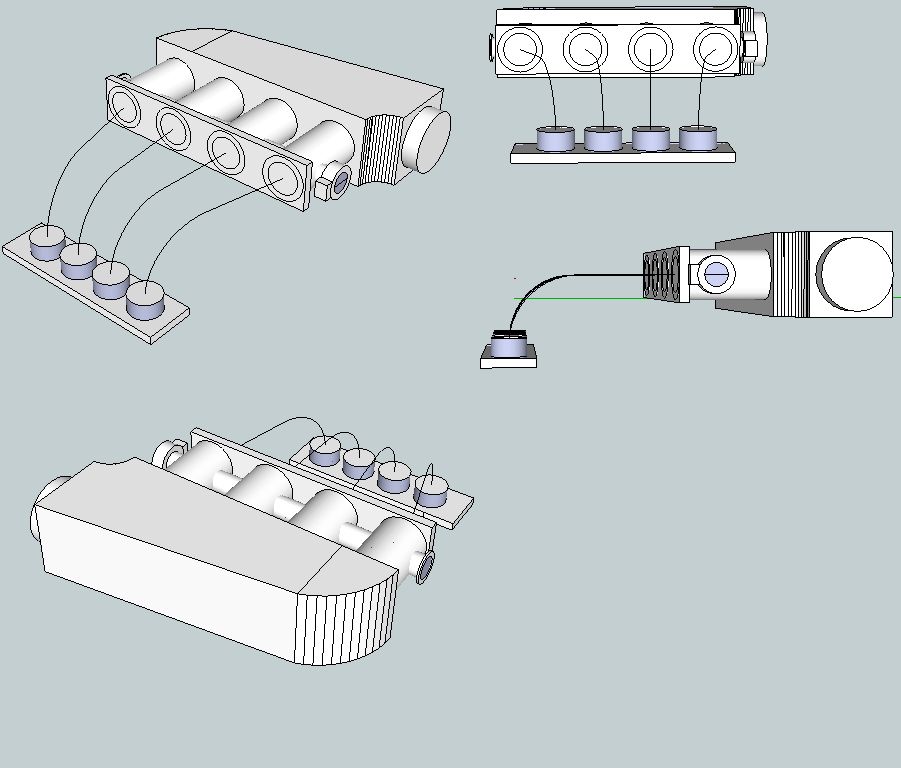

Going to modify the T2 LIM(since it means i can use the stock fuel system, and i can't realy afford to fit that into my budget at the moment), and make a new UIM. The modifications i plan to do on the T2 LIM for it to suit my build: Fit a runner from pp's to the primary runner, and port up the primary runners from where the pp runner is connected up to the flange. Here is a sketch of how i plan on building the UIM(can't figure out how to make bent piping in sketchup without using a lot of time, so the lines from the flange to the tb's are supposed to be 42mm ID pipe.)  I have all the parts i need, so i will start on the UIM today. |

|

|

|

|

|

#97 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

42mm x 4 flowing full time is a lot of pipe to fill.

You're going to lose a lot of low end power because the pipes are that big. -Ted |

|

|

|

|

|

#98 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

Hmm, so i might be just as well off using the stock T2 UIM until i can make a complete new intake then?

|

|

|

|

|

|

#99 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

Took a pressure test of the coolant system, and turned out there was a leak, the front iron must have had a weakness in the coolant seal groove, cause it had broken loose while assembling the engine, very glad i found that now and not with the engine running.

So new Front iron on the way from UK. While i wait i have taken care of some other small stuff. Pfc is installed and the stock fc engine idles and drives ok with the base map, decided to test it on a engine and sensors i know work, so i can be shure that any problems with the semi pp engine, won't be related to the PFC hardware. Built new exhaust from the header and back, used 2,25" SS pipe and v-bands, so it will be easy to take it down and modify later if nececary. Have removed the old speaker shelf since i wasn't realy happy with how it looked, installed a new sub, should take about 10min to change out the sub for the rear tower strut.     Could clean up the wiring, but it's not realy a priority.

|

|

|

|

|

|

#100 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

Changed to my spare door, and went from a lexan to glass window(finally).

Hmm, i think the old window might be beyond repair...  That was easy, no special tools needed   Removed the unececary wiring from the car, only thing going out to the door is power window/mirror.  Better than before, but i am realy looking forward to getting to the point where i can get it back to one color.

|

|

|

|

|

|

#101 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

So got the new iron, ported it and assembled the engine with the semi pp housing, and the coolant system did not hold pressure. So i dissassembled it and found out that both the semi pp housings had leaks thru the filler used around the p ports, so i will nee to repair those before they can be used.

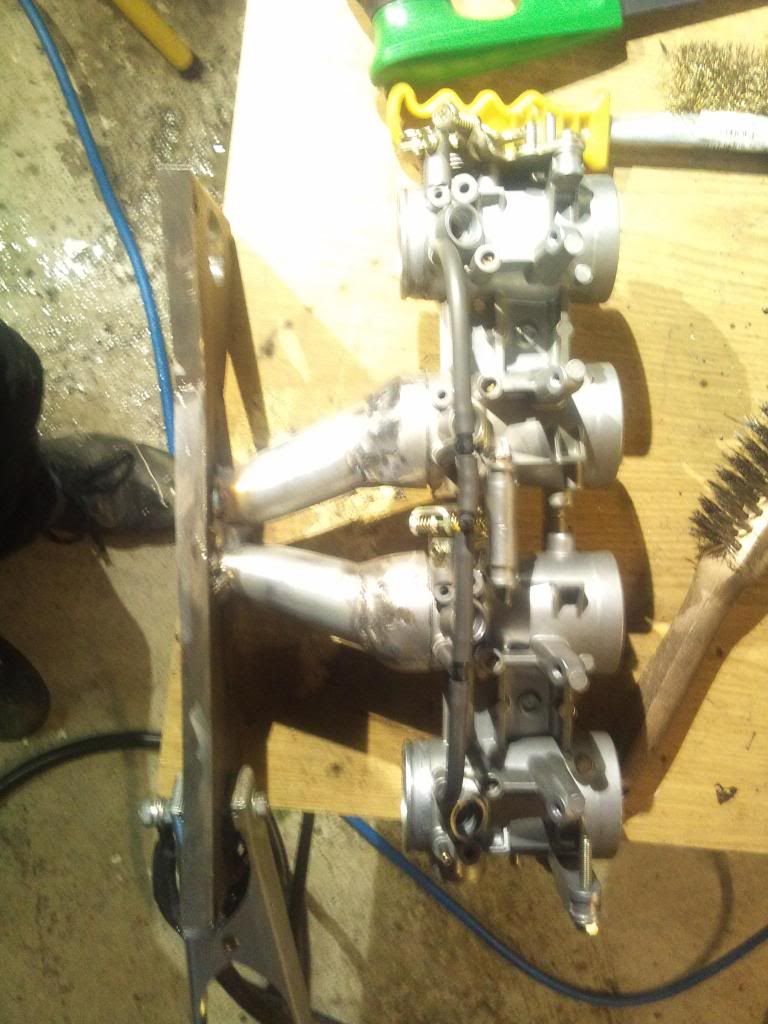

I decided to use the old T2 housings and just get the engine buildt and in the car, and then i can add the Semi pp housings on the next rebuild instead. Assembled the engine with the stock housings and the cooling system not held pressure. Shortblock nearly done:  Started on the ITB setup, made a flange from 12mm mild steel. Still needs some more work to the ports and cleaning up around the flange, but that can be done after the runners are made and welded on.

|

|

|

|

|

|

#102 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

|

|

|

|

|

|

#103 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

Some stuff has happened since i last posted.

Car is now matte black, engine is in with T2 turbo intake (itb setup did not have enough clearence to the exhaust, so it's on hold for now). Also converted it from 4 -> 5 bolt. I have gotten myself a daily driver, so the FC will not be on the road and will only be used for one or two track weekends each year for the next three years since i have just started on a bachelor degree in engineering. Got plates back on the car, atleast for a couple of months, feels great driving it around again  Ran a little rich, around 10 AFR. I have adjustet it a little and it now runs around 12 AFR at idle, and runs good enough now for me to get it to a friend with a dyno, so i can get it properly tuned and see what kind of power i will have to play with     Adjsted the map a little and hit 175whp on my friends dyno. For comparison his Dynocom dyno measured 500whp on a car that got 600whp on a Dynapack the previous day.  http://youtu.be/9x1xrD-nwvQ |

|

|

|

|

|

#104 |

|

Brokeback Power!

Join Date: Feb 2008

Posts: 290

Rep Power: 18  |

very nice!! i love seeing updates to build threads!! Sad that the ITB had to be put on hold, but it seems like you're having a lot more fun right now

|

|

|

|

|

|

#105 |

|

Rotary Fanatic

Join Date: Mar 2010

Location: Norway

Posts: 163

Rep Power: 16  |

|

|

|

|

|

| Bookmarks |

|

|