|

|

#211 | |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

I've seen oil leaking from the oil cooler fittings at the oil cooler somehow whip back and end up coating the bottom of the trans! You gotta remember that air flows from the front, up and over and under the engine...  Just a quick note on this pic... Red circle shows an exhaust gas leak. It should have a similar mark on the turbo exhaust manifold. Gasket looks okay... Was the turbo exhaust manifold not bolted down tight enough? Crack? -Ted |

|

|

|

|

|

|

#212 | ||

|

RCC Contributor

Join Date: Mar 2008

Posts: 505

Rep Power: 18  |

Quote:

That being said, Yes, IIRC I did have problems getting the front of the exhaust manifold bolted down. On the first rebuild, after the engine had been installed I then made the untimely decision to put new exhaust gaskets on. I do remember having trouble getting the front manifold nuts tightened down correctly. But also as this pic shows, I do have cracks in the manifold. They were there when the initial rebuild happened last year, I was hoping they were not long enough to cause a leak.  I have a spare S5 turbo manifold in storage, I'll get that either later tonight or tomorrow morning. I remember that the manifold wasn't in perfect shape, but that's as much as I remember. What I don't know is what to expect from symptoms of an exhaust leak at that location. Louder exhaust, but what else? I have heard of people welding and repairing cracks, but I've also heard that often times that the welded repair then becomes a problem down the road. It sounds like repairing those cracks are more a temporary fix than an long term solution. But the reason I'm bringing up temporary fixes is that this summer I will be taking welding classes. It is possible that this summer I will meet someone through the instructor of the class who could weld a new manifold for me. If I could learn to do the work myself that would be better, but might be a little ambitious of an expectation from an entry level welding class.

__________________

Quote:

1990 Vert/ S5-JDM 13BT (rebuilt but with issues I'm working out). Rtek N370 1.7, 550/800 injectors, FD fuel pump, RB REV TII exhaust, Tein springs and Illuminas Last edited by JustJeff; 01-09-2013 at 06:14 PM. |

||

|

|

|

|

|

#213 | ||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

The red arrows goes to the two, obvious cracks. Most of the time, you just worry about the cracks. It looks like in your case, the entire area between the two cracks has shifted. Encircled in red... This would explain the soot marks on the gasket. To fix this case, you'd need to first weld the cracks and then machine down the flange flat. Unless you've got the resources to do this, it's way too much trouble. Small exhaust leaks start out as ticking sounds... As they get worst, they progress to a pfft...pfft...pfft and sometimes whistling sounds like old-school VW engines. Quote:

The consensus on these turbo exhaust manifolds is that you either got a good one or you don't. Many of them warp - due to the metal content. Some of them warp (and crack) to the point where they are junk. It's usually easier and cheaper just to replace. -Ted |

||

|

|

|

|

|

#214 |

|

Rotating Assembly

Join Date: Oct 2008

Location: TX

Posts: 102

Rep Power: 18  |

I've found Verocious Motorsports to be great for silicone and all the other fab stuff. Their prices are usually really good and they ship really fast too.

I bought a bunch of stuff from them and have always been pleased so maybe you'll find them useful too. Bummer about the manifold.

__________________

90 S5 Vert. JDM Tii with BNR Stage1 turbo. Pineapple Racing street port. Bonez cat-forward. Corksport cat-back with Vibrant UltraQuiet resonator. RTek 2 wZeitronix w/b. HKS EBC. Vis CF Tii hood. 3000GT wing. Ground Control coilover kit with KYB AGX shocks. Red and Black leather RX8 seats. Corksport Odura lip & bumper caps, OEM Tii skirts |

|

|

|

|

|

#215 | |

|

RCC Contributor

Join Date: Mar 2008

Posts: 505

Rep Power: 18  |

Thanks for the heads up vrracing. I'll check them out.

As for the exhaust manifolds I pulled my spare one from storage and it's no better and has cracks in just about the exact same location. I stopped in the trusted machine shop I've been using to ask about repairing the manifold. He's prognosis was not good for either manifold. It would cost me around $100 to attempt to repair one of them. His concern is that once they start heating up the manifold the cracks will extend and become unrepairable. I haven't made much progress in getting the engine torn down. I've got a what I think is a bad rotator cuff in my right arm. It's quite miserable in that simple range of movement trying to reach across my body, behind me, over my head, or reach out for something lights up my arm like crazy. Getting the flywheel off today was about all my arm could take.

__________________

Quote:

1990 Vert/ S5-JDM 13BT (rebuilt but with issues I'm working out). Rtek N370 1.7, 550/800 injectors, FD fuel pump, RB REV TII exhaust, Tein springs and Illuminas |

|

|

|

|

|

|

#216 | |

|

RCC Contributor

Join Date: Mar 2008

Posts: 505

Rep Power: 18  |

Engine is torn down. What does a failed coolant seal physically look like? I didn't find any blown out coolant walls. I didn't find any seals broken in half, but I did find two inner coolant seals shreaded quite easily. But that seemed almost normal for the inner.

I have not started cleaning parts yet and snapped some pics of what I think are suspicious looking coolant seals still in the grooves.  This spot was splitting at the seam, but also at the bottom of the pic.  Something bad did happen while transporting the engine after the flywheel and front bolt had been broken free. Engine came free of it's restraints and rolled in the back of the van. I'll get some pics tomorrow of my front and rear iron for opinions.

__________________

Quote:

1990 Vert/ S5-JDM 13BT (rebuilt but with issues I'm working out). Rtek N370 1.7, 550/800 injectors, FD fuel pump, RB REV TII exhaust, Tein springs and Illuminas |

|

|

|

|

|

|

#217 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Can you take a wide angle view of the entire surface of the irons?

Sometimes you can see a discoloration in the area of the coolant leak... -Ted |

|

|

|

|

|

#218 | |

|

RCC Contributor

Join Date: Mar 2008

Posts: 505

Rep Power: 18  |

Here is my big concern. The engine was being transported after having the flywheel nut and front stack nut broken free. It came free of restraints and rolled. Torsion bearing was damaged and one of the cylindrical bearings fell into the engine. My assumption is that there will be an oil leak at that location from there being too much space between surface and oil control ring???

Here are some wider angle pics of irons.   Different pic of same middle iron facing   I didn't notice this while taking the pics, but did while moving pics from smartphone to computer. Rust in the seal channel?

__________________

Quote:

1990 Vert/ S5-JDM 13BT (rebuilt but with issues I'm working out). Rtek N370 1.7, 550/800 injectors, FD fuel pump, RB REV TII exhaust, Tein springs and Illuminas |

|

|

|

|

|

|

#219 | |

|

RCC Contributor

Join Date: Mar 2008

Posts: 505

Rep Power: 18  |

Are these deformations significant?

__________________

Quote:

1990 Vert/ S5-JDM 13BT (rebuilt but with issues I'm working out). Rtek N370 1.7, 550/800 injectors, FD fuel pump, RB REV TII exhaust, Tein springs and Illuminas |

|

|

|

|

|

|

#220 | |||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

Typically, the stock inner water jacket o-rings tend to "delam" when removed. The inner, orange stuff is silicone. The outer white "liner" is Teflon? The two materials don't adhere to each other too well. One side note... Mazda recommends putting the "seam" of the inner water jacket o-ring seal toward the intake port. At this location, this is the area where that seal sees the least amount of stress - heat and pressure. I noticed that you got your seams in approximately the 12 o'clock position almost dead top. Quote:

The seal has no where to go, so as long as the tear doesn't grow, the seal should stay intact. Quote:

Does it pass the fingernail test? Can you tell it's a depression by running your fingertip over it? -Ted |

|||

|

|

|

|

|

#221 | |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

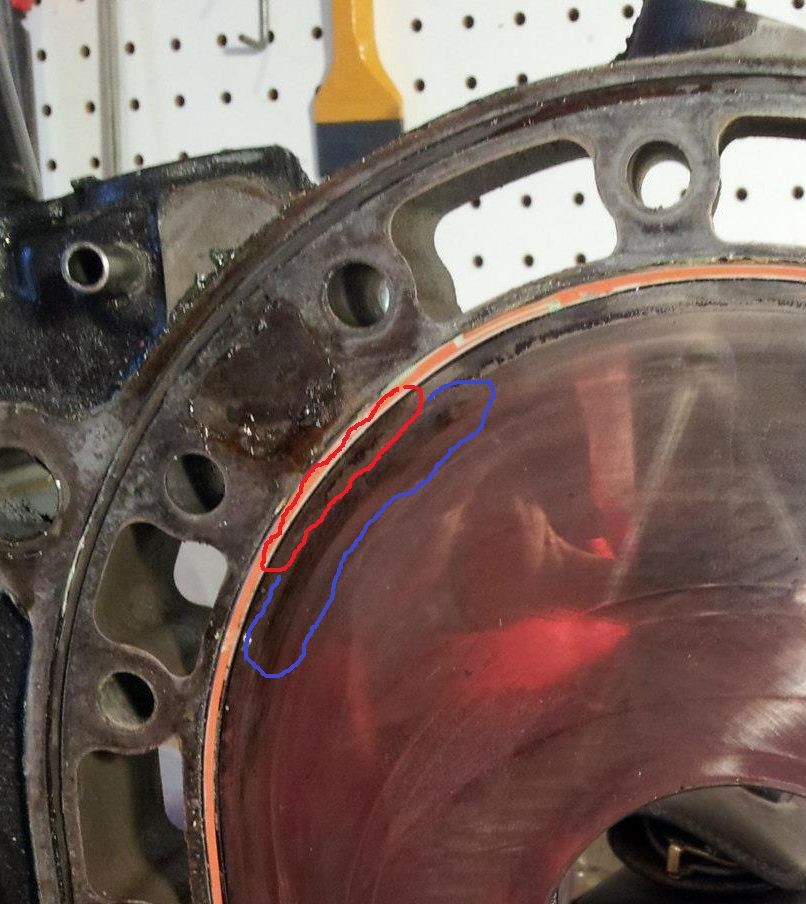

Assuming the irons were cleaned methodically, the rust was not there upon assembly. It's safe to say that the rust formed after the engine was put together, so coolant was getting past the seal somehow... Not good. I've cropped one of your pics here...  Red circle shows possible sign of coolant entering the combustion chamber. Looking at the orientation of the iron, this would be the "top" of the combustion cycle. Blue circle shows the coolant trying to burn inside the engine - coolant doesn't burn well so it leaves traces like this... This would be my guess where the coolant leak came from. -Ted |

|

|

|

|

|

|

#222 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Again, like the cuts, usually not a big deal...

Seal has no where to go. These dents are typical when using some kinda supplemental sealant with the water jacket o-ring? Petroleum jelly? Hylomar? -Ted |

|

|

|

|

|

#223 | ||

|

RCC Contributor

Join Date: Mar 2008

Posts: 505

Rep Power: 18  |

Quote:

About the damage on the front iron. I've reposted the pic. The circled area you can catch your fingernail on. It's been almost a week since I've touched the front iron....but as I remember it you can feel a depression but can only catch your nail in the circled area. I'll reconfirm that later today.  I used hylomar

__________________

Quote:

1990 Vert/ S5-JDM 13BT (rebuilt but with issues I'm working out). Rtek N370 1.7, 550/800 injectors, FD fuel pump, RB REV TII exhaust, Tein springs and Illuminas |

||

|

|

|

|

|

#224 | |

|

RCC Contributor

Join Date: Mar 2008

Posts: 505

Rep Power: 18  |

I have gotten myself confused while checking my irons for warpage. I'm confused about the difference between checking for warpage and checking for step wear.

Warpage tolerance is 0.0016 Step wear tolerance is 0.003 Doesn't that mean there are areas on the combustion surface where step wear tolerance is higher/greater than warpage tolerance? I check my tolerance for warpage per the FSM at 4 points. Once I get into oil seal wear area there is an even greater tolerance(0.0008) and my 0.0015 feeler can slide under my straight edge. I'm also taking the straight edge across areas other than the 4 pts in FSM and finding some variations. Can someone help clarify. Also does anyone know if the Pineapple Racing streaming videos are down? I used them for my previous rebuild and they were incredibly helpful. I sent them an email today but I expect I won't get a response till Monday. Last question for this post. With that damage on the front iron on the rough, non-combustion area but then extending into oil ring area and possibly into side seal area.  What will the be the result of using that iron on the engine. I'm not seeing any irons for sale and am considering using the iron?

__________________

Quote:

1990 Vert/ S5-JDM 13BT (rebuilt but with issues I'm working out). Rtek N370 1.7, 550/800 injectors, FD fuel pump, RB REV TII exhaust, Tein springs and Illuminas |

|

|

|

|

|

|

#225 | ||

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

Quote:

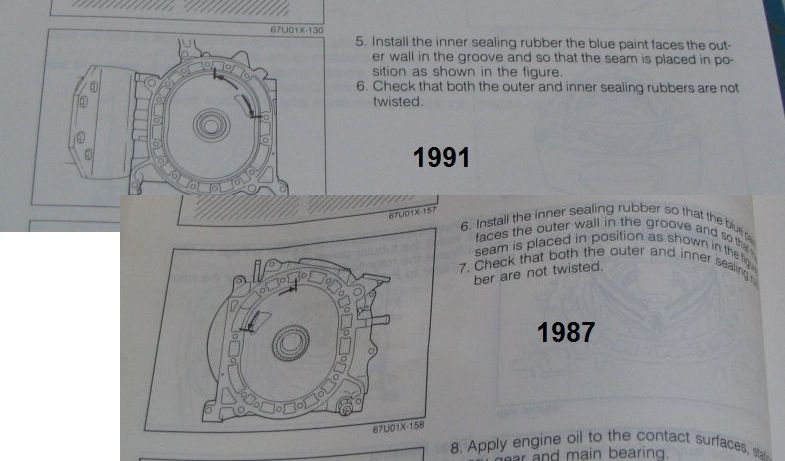

I prefer to put the splice where the intake ports are located. This is the coolest area in the housing. Sorry for the bad pics, but these are pics from the 1987 and 1991 FSM's...  Quote:

Also, do you have your oil control labeled so you know which one goes where? This might help, but can you mic out the height of the oil control metal rings? If that area is affecting the oil control ring, it could be abrasive enough to cause the oil control ring to wear prematurely. -Ted |

||

|

|

|

|

| Bookmarks |

|

|