|

|

#361 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#362 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

I bought a bunch of new rotors. How do I comfirm that they are 9.7:1-compression?

I have weight them, but all the newer rotors have the same weight. The 28cc in the comb-chamber are kind of tricky to check, or? |

|

|

|

|

|

#363 |

|

Still Building my FD

Join Date: Jun 2009

Location: Pasco, WA

Posts: 255

Rep Power: 17  |

Your build up is awe-inspiring!

__________________

Uh.... hi. |

|

|

|

|

|

#364 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#365 |

|

VRR PSSH

Join Date: Apr 2009

Location: Sarasota, FL

Posts: 113

Rep Power: 17  |

This is one of the best build threads ever. Thank you for sharing this.

__________________

1993 SSM, 20B (D449), SINGLE-TURBO, DIY-BUILD IN THE WORKS... |Build Thread| 1993 BB, 13B, SINGLE-TURBO, DAILY DRIVER |Build Thread| MY FACEBOOK PROFILE // BLACK LABEL ENGINEERING // ADVANCED RACE TECH // IR PERFORMANCE // THE BOOST LAB // [url=rotaryaddicts.com] |

|

|

|

|

|

#366 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

|

|

|

|

|

|

#367 |

|

Home-brew Rotary

Join Date: Feb 2008

Location: GooseCreek SC

Posts: 552

Rep Power: 18  |

Just staring at that front end.

Nice work.

__________________

'89 RX7 GTU, half-Bridge-port S4/S5 NA, E6K, Full RB exhaust, weekend warrior. '83 RX7, The "this might take awhile" project. '87 RX7 GXL, Rest In Pieces. '98 Subaru Impreza Outback-sport, rx7 rescue vehicle, down for repair. '94 Ford Ranger, daily. |

|

|

|

|

|

#368 |

|

Rotary Fan in Training

Join Date: Jun 2008

Posts: 38

Rep Power: 0  |

Amazing build. I need access to some of those tools! Just the raw material for the engine would break my budget, haha. Can't wait to hear the startup video.

|

|

|

|

|

|

#369 | |

|

rotaryevolution.net

Join Date: Feb 2011

Location: Las Vegas, NV

Posts: 248

Rep Power: 15  |

Quote:

turbo rotors also have a T stamp embossed into the oil relief vein area facing the center iron, n/a rotors have no T stamp, just a I and II for front and rear(which accompany the T on turbo rotors). that said, the quickest and easiest method is just check the oil galley in the rotor for the T stamp(or lack thereof in this case) and make sure the rotor has a machined pocket for the series 5. if you somehow managed to get renesis rotors they're a little less conspicuous with their scallops and thick side seal lands.

__________________

http://rotaryevolution.net Last edited by Rotary Evolution; 09-25-2013 at 09:37 PM. |

|

|

|

|

|

|

#370 |

|

The Newbie

Join Date: Aug 2013

Posts: 28

Rep Power: 0  |

Neat!

|

|

|

|

|

|

#371 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

Have lately spent some time with the porting of the engine. Most in SolidWorks, but also in reality.

Thought I run with V-band instead of what is in the renderings. However, I must turning one half of the V-band myself, and it seems difficult to find the measure of it. If anyone has seen it, or know how they should look like, I am receptive :-) Happy to metric! The tubes I intend to use is 50x2, ie 46mm internally. |

|

|

|

|

|

#372 |

|

Rotary Fan in Training

Join Date: Sep 2013

Location: Winder, Ga

Posts: 42

Rep Power: 0  |

An engineering marvel! very impressive!

|

|

|

|

|

|

#373 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

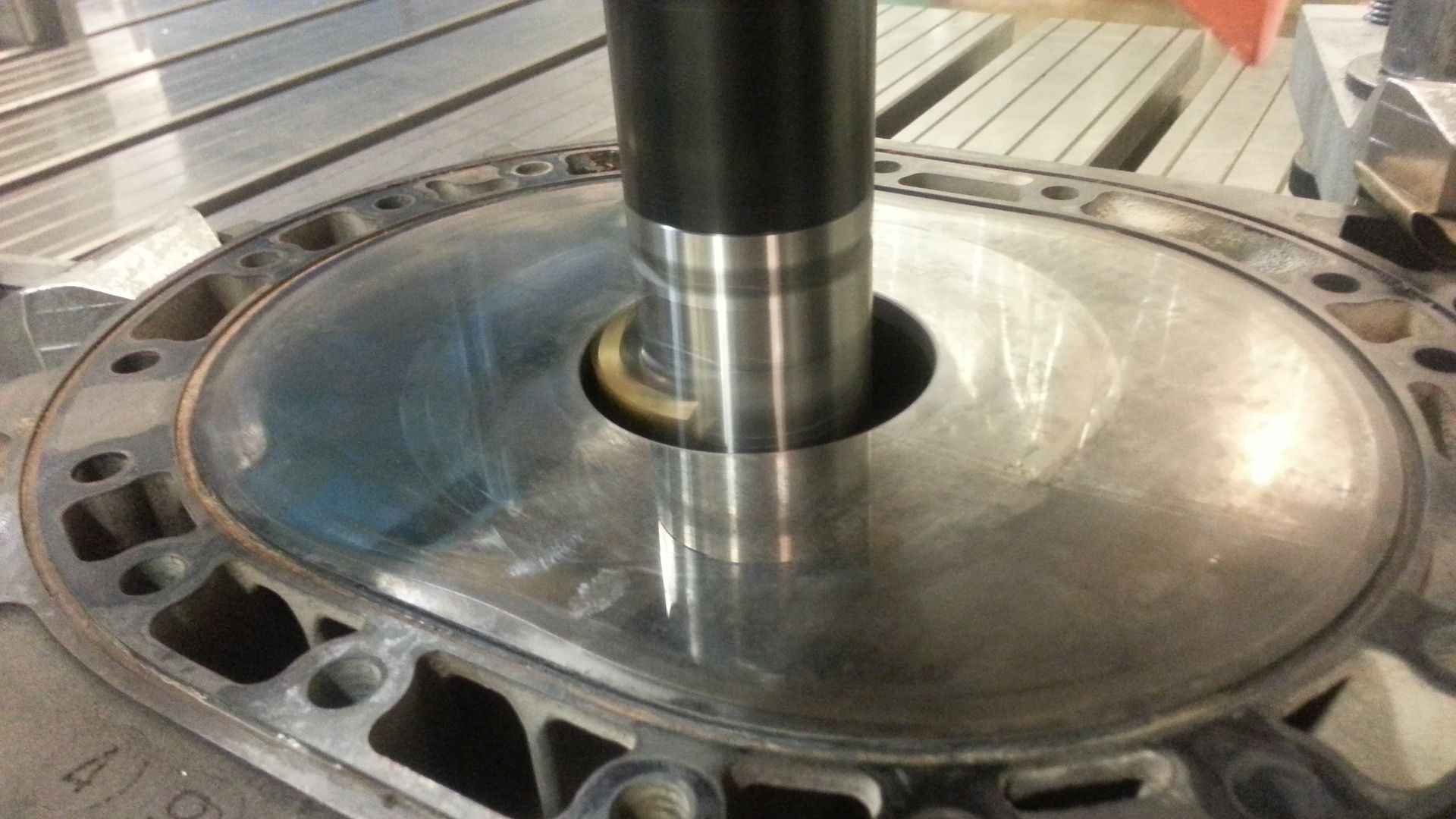

Continued today with the trash-housing.

Did a test sleeve in the cnc-lathe. I am very satisfied with this. Have minor improvements to do with the real ones later.

|

|

|

|

|

|

#374 |

|

I have radioactive semen

Join Date: Jul 2008

Location: in a bottle of Glenfiddich

Posts: 250

Rep Power: 18  |

agreed ... and yet still i still find the words so bloody inadequate.

|

|

|

|

|

|

#375 |

|

Rotary Fanatic

Join Date: Feb 2011

Posts: 210

Rep Power: 15  |

I have been thinking about the intake. I would want to have tapered runners, but because "someone" decided to lower the entire body over the frame, there isn't much space above the engine.

This means that I have to make a turn on 156.5grd pretty tight around the engine and land on the block. The options are to cast runners in plastic, carbon fiber or aluminum perhaps? Today I continued to mod my intermediate irons for more bearings. First I layed a the intermediate and clamped it. Then either front or rear iron onto to indicate the centrum.  Machined two new very tight dowels. As tight as possible. Even then you can move the plate 0.015mm in both directions. I alinged in the middle of the play.

|

|

|

|

|

| Bookmarks |

|

|