|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|||||||

| Rotary Tech - General Rotary Engine related tech section.. Tech section for general Rotary Engine... This includes, building 12As, 13Bs, 20Bs, Renesis, etc... |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

Displacement on demand

So today I was waiting for some parts, so I decided to test a theory that I have had for a while.

My theory is that if I am pulling 45 kPA of vacuum in my intake manifold while driving down the road I either need new gearing or some other technique for increasing the load on the engine (so that less energy is wasted pumping air across the throttle plates). The engine only pulls 71 kPA of vacuum to stay at 2,700 RPM (cruising speed). Due to the complete lack of taller gearing for my transmission and/or differential. I opted to test plan B - Displacement on Demand (DOD). I did my before testing on the same stretch of road about 2 hours earlier in the day and datalogged the trip to compute fuel economy. My test setup was somewhat simple - I simply turned the idle up to 1600 rpm and then unplugged the power wires to the coil packs for the front rotor. This resulted in an immediate drop to about 900 RPM idle (which was fine). My testing began at this point. I put my gauge page up on my computer, plugged in the inverter and went for a drive. After about 10 miles on the interstate (+6 miles to get there), I decided to switch which rotor I was running on, so I pulled over, plugged in the front rotor coil packs and unplugged the rear rotor coil packs. I drove the 10 miles back home on the interstate and decided that all was good, so I plugged the rear rotor back in and drove the 6 miles home. I had two problems: The first was in the driveway while adjusting the idle - the engine stalled on the first try (rotaries don't start as easily on one rotor as they do on 2). The second was that I was idling at a stop sign and my electric fan kicked on, causing the engine to stall (equally annoying to get running again). Obviously, for this test I got terrible fuel economy, because I was still pumping fuel through the unfiring rotor, but the numbers listed below are indicative of instantaneous fuel economy at steady-state as calculated from injector energized duration (Assuming that the fuel was not flowing to the inactive rotor). Baseline Average: Traveling East: 35.3 mpg instantaneous Traveling West: 29.0 mpg instantaneous With DOD: Traveling East: 45.2 mpg instantaneous (ran about 70 mph consistently) Traveling West: 37 mpg instantaneous (I lost speed on a couple hills with the headwind) My vacuum levels were: Baseline Average: Traveling East: -53 kPA Average Traveling West: -38 kPA Average With DOD: Traveling East: -25 kPA Average Traveling West -5 kPA Average Now I am thinking about building an external controller that switches between the rotor at approximately a 30 second per rotor rate with a controlled transition. DOD mode would be activated by the throttle being below a certain level for 15 seconds or so. I would need some idle logic too (otherwise the e-fan kills the engine). What do you all think?

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) |

|

|

|

|

|

#2 |

|

RCC Addict

Join Date: Mar 2008

Location: Honolulu, Hawaii USA

Posts: 1,813

Rep Power: 19  |

The problem with D.O.D. engines is the nasty harmonics it induces due to the "misfires".

I predict your engine is going to eat itself by the end of the year. More accurately, it's going to kill all it's bearings and - in extreme - the e-shaft too. -Ted |

|

|

|

|

|

#3 |

|

Still Building my FD

Join Date: Jun 2009

Location: Pasco, WA

Posts: 255

Rep Power: 17  |

wow... what if you produced a logic that literally just cut out half the injector pulses, alternating each rotor and half the spark (hopefully correlating ;-) )

|

|

|

|

|

|

#4 |

|

destroy, rebuild, repeat

Join Date: Feb 2008

Location: Charleston, SC

Posts: 395

Rep Power: 18  |

interesting idea. even if you made a logic circuit to cut out certain injection pulses, i think you would still have the vibration problems reted mentioned. but it would be a cool experiment to find out the effects

as far as economy mods, the other thing I want to try is modifying the throttle body. If you look at the way the plates work, you can barely open the primary before the secondary plates start cracking open. I think there are some mpg to be gained by keeping the secondary plates closed like cruising

__________________

1993 RX-7 Touring MB, stockport 13B-REW, 9.4CR rotors, T04S 60-1/p-trim single turbo 1986 RX-7 Base project track beast |

|

|

|

|

|

#5 |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

I'm going to be frank here. I think the gains in MPG to be had are going to come in the transmission, differential, and wheels. Increasing the transmission and differential alone will yield a large percentage of the MPG increase. Thinner wheels (reducing rolling resistance) will also increase your gas savings quite largely.

The engine itself could save on MPG by cheating it a little bit. Mixing of various fuels (IE LPG) to decrease the required fuel from the normal fuel source, but that's just ignoring the other fuel costs. For increasing engine efficiency look at the intake itself. If you lower the air intake via a restrictor you lower the required fuel. This of course comes at a cost of a less horsepower, but you aren't going for hp when you're thinking of MPG. To regain the hp you can install a bypass which will allow the addition of more air when the TPS is increased beyond a certain rate. This should remedy the lack of power, but again at the cost of MPG. I personally think that's the best bet beyond running on one rotor. Additional saving could be had from ensuring the intake adheres to the hemholtz equation throughout the RPM band. Thereby increasing volumetric efficiency just by running the engine.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group Last edited by vex; 05-09-2011 at 11:19 AM. |

|

|

|

|

|

#6 |

|

Rotary Fanatic

Join Date: Mar 2008

Posts: 123

Rep Power: 18  |

two things;

1. PJ showed me this years and years ago, but it might work, http://yarchive.net/car/air_induction.html 2. second i've noticed tuning a few cars that going from say 12:1 afr at cruise to 15:1 at cruise "looses power", my gsl-se particularly used to do this when the sensor in the radiator switched it into closed loop, the car would feel torquey, and then when it switched to closed loop, "loose power". but if you think about it backwards, you say it takes X amount of fuel to go 25mph, and @12:1 afr, you have to open the throttle Y percent. when you switch to 15:1 afr, the amount of fuel you need to go 25mph is THE SAME, but the amount of air is bigger so you need to open the accelerator MORE. y+(15:1/12:1) i hope that makes sense, its easy just to think of the gas pedal as a linear power delivery lever, but with a carb particularly, you can get fuel and air to be separately metered (weather you want it or not!). a lot of new cars in europe have a "stratified charge" mode, where i think the throttle opens, and its fuel controlled like a diesel. i don't know exactly how you'd implement it on a rotary... mike |

|

|

|

|

|

#7 | |

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|

|

|

|

|

|

#8 |

|

Rotary Fanatic

Join Date: Mar 2008

Posts: 123

Rep Power: 18  |

i had an NSU spider and the ports are really weird!

its a 1 rotor P port, with similar dimensions to a 10A rotary actually. it actually has 2 intake ports, one TEENY primary port, that opens late, and closes late, and then its got one bigger port under it. and a 2 barrel carb bolts right to the rotor housing. hell this literally is the car right here... http://www.rotarycarclub.com/rotary_...ead.php?t=1670 |

|

|

|

|

|

#9 | |

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

Quote:

As to the intake idea, I already have a restrictor (my throttle plate) and it is the very element that is destroying my fuel economy. My bypass is activated when I open my throttle plates. Think about it this way: Based on rolldown analysis, it requires 12 Hp to go 60 mph in my RX7. At 60 mph, I am running 2400 rpm and -48kPA MAP. The engine is turning 40 revolutions/second - amounting to 1.3X40 or 52L of air per second being pumped against a 48 kPA head (plus exhaust backpressure - which I am ignoring for this calculation). Since pump horsepower is simply W = QP, I can convert the units to m3/s and N/m2 and I get 0.000052 m3/s * 48000 N/m2 = 2.5 kW = 3.5 Hp. This is just the flow work to pump air across the throttle plates, and it amounts to 30% as much power as is required to drive down the road. Intake restrictions (whatever they are) do not really help fuel economy. To add to the above calculation, let me do some quick math on the thermal efficiency of my engine. at 2400 RPM, the engine puts 100 Lb-ft of torque to the wheels. This is with an injector on-time of 4.8 ms (primaries, per rotor) with no intake vacuum. At 48 kPA, I am running 2.6 ms injection time and putting 26 Lb-Ft of torque to the wheels. This is more than half the fuel and about 1/4 as much torque. (Efficiency of less than 50% WOT efficiency). This is the big reason that I tried DOD, unfortunately, I have no valves to hold open, so I still do a lot of work moving the air through the second rotor while generating no power with that rotor. The increase in efficiency is the only reason that DOD makes sense. As to the tires, I am running Bridgestone Ecopia 195/65/R15s (Low rolling resistance). They improved my 30 mph and below fuel economy substantially (about 10 mpg) over the 245/40/R17 Goodyear Eagles that I was running before, but at 70 mph, there is about 1 mpg difference (the overwhelming majority of the drag at 70 mph is aerodynamic). I am running dyno fluids in my transmission and differential, I picked up almost 1 mpg average by using synthetic in my NA drivetrain (so that is still on the table).

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) Last edited by NoDOHC; 05-10-2011 at 06:26 PM. |

|

|

|

|

|

|

#10 | |

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

Quote:

I didn't even consider this, now you have me a little bit worried. However, let me list my experiences: I knew a guy who purchased an FC (this was about 10 years ago when they were $100 each) with a 'blown engine' we got it running (on one rotor) and disconnected the injectors for the dead rotor (to keep from damaging the exhaust) and he drove the car for 5,000+ miles just like that. He loaned the car to a friend who smashed it up a little and decided that he would fix the damage really quickly (headlight doors, etc.) He opened the hood and observed that the secondary injector was unplugged and he thought that he had figured out why the car was so gutless. He took the manifold apart, plugged the primary back in, put it all back together and 'fixed' the problem. The other rotor had apparently started making compression again some time during that 5,000 miles. The point is that the car ran great on both rotors, he ran it for a while after that and never had any issues. This was with continued operation on the same rotor for 5,000 miles. I never saw this engine apart so I can't attest to the bearing condition, but the engine made good oil pressure and ran well. I also had a friend who blew a rotor in New York while on his way to Nebraska. He unplugged the injectors to the dead rotor and drove all the way to Nebraska and back on one rotor. I helped him rebuild his engine and the good rotor looked like brand-new (not even any carbon) his bearings had no damage at all, we re-used all of them. In fact, I put the good rotor in a different engine after his blew up a second time. The bearing problem might be a turbo-only failure (I hope).

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) |

|

|

|

|

|

|

#11 | |||

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

Quote:

Quote:

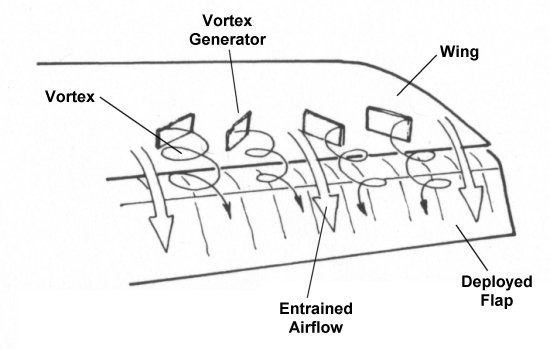

Granted those aren't going to work for you, but those will reduce the friction acting on the car dramatically (which technically speaking is a hell of a trade off). As for the aerodynamic effects I completely agree. If you really wanted to improve your MPG at speeds over 60 MPH you'd want to install a couple of these:  The ideal location I would think would be directly in the front of the hood... but that's just a guess. Possibly putting them on the rear roof line might actually prove more beneficial, but both might be tested on the highway for verification of greatest increase. Drag reduction by use of the vortex generators will have significant effect on the Cd. The idea is that it sort of 'trips' the boundary layer causing it to not necessarily reattach to the surface but follow the contours still. In essence rolling along on bearing of air over the skin of the car. If you don't care too much about looks you might be able to try some artificial 'shark skin' which is used on marine hulls to reduce drag. The effect is going to be similar... but I don't know any place that would sell 'em.

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

|||

|

|

|

|

|

#12 | |

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

Quote:

It is a good idea, I would definitely give it a try if I hadn't already tried it.

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) |

|

|

|

|

|

|

#13 | |||

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

Quote:

Quote:

Quote:

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) |

|||

|

|

|

|

|

#14 | ||||

|

The quest for more torque

Join Date: Sep 2008

Location: Sheboygan, Wisconsin

Posts: 855

Rep Power: 18  |

Quote:

Higher vacuum in the intake manifold is all bad (think about the flow work to pump air through the engine from that pressure to the exhaust manifold pressure, without even considering the chemical and thermodynamic implications). Helmholtz tuning could possibly help, but the required intake runner size to get enough air velocity to see any appreciable benefits from Helmholtz would give up way more power than I am willing to give up. If the intake runner can provide even 0.1 Mach at 2400 rpm and 45 kPA pressure drop, They would have a tiny cross-section and would be something like 5 feet long. On top of that Helmholtz would only help for a very limited speed range. I really should have done a better job of explaining my goals for this plan, I want my cake and I want to eat it too. I want a 250+ Hp rotary that will still give 35 or even 40 mpg. Quote:

I really do sound like I am being unrealistic, but I have a Metro if I want to drive for cheap, I want the RX7 to get decent mileage to see if I can. I also want it to retain some semblance of pleasure to drive, otherwise I might as well drive the Metro. Quote:

Quote:

__________________

1986 GXL ('87 4-port NA - Haltech E8, LS2 Coils. Defined Autoworks Headers, Dual 2.5" Exhaust (Dual Superflow, dBX mufflers) 1991 Coupe (KYB AGX Shocks, Eibach lowering springs, RB exhaust, Stock and Automatic) |

||||

|

|

|

|

|

#15 | ||

|

RCC Loves Me Not You

Join Date: Jul 2008

Location: Influx.

Posts: 2,113

Rep Power: 20  |

Quote:

Quote:

http://www.zenith.aero/profiles/blog...g-micro-vortex

__________________

The Official FC Radiator Thread My Project Thread: Cerberus CCVT Virginia Rotary Group |

||

|

|

|

|

| Bookmarks |

|

|